Mobile No.

+91 97663 36366

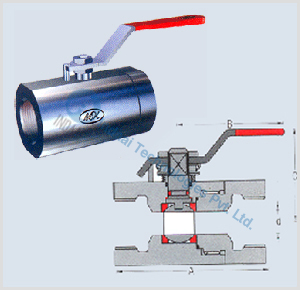

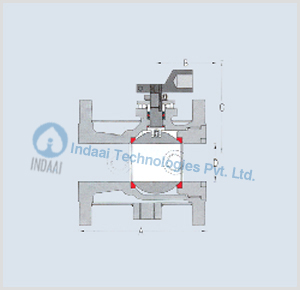

DESIGN STD : BS EN ISO 17292 (BS 5351) TESTING STD : EN 12266-1

Test Pressure in bar (psi) |

|

Pressure rating |

Class 800 |

Hyd. Shell |

207 (3002) |

Seat |

Refer Technical Data |

Air Seat |

6.9 (100) |

Dimensions are in mm (inch) |

|||||

SIZE mm (Inch) |

A |

B |

C |

D |

Wt1) |

8 |

70 |

110 |

51.0 |

9.5 |

0.5 |

(1/4) |

(2.8) |

(4.3) |

(2.0) |

(0.4) |

(1.1) |

10 |

70 |

110 |

51.0 |

9.5 |

0.5 |

(3/8) |

(2.8) |

(4.3) |

(2.0) |

(0.4) |

(1.1 ) |

15 |

70 |

110 |

51.0 |

9.5 |

0.5 |

(1/2) |

(2.8) |

(4.3) |

(2.0) |

(0.4) |

(1.1) |

20 |

80 |

110 |

54.0 |

13.0 |

0.8 |

(3/4) |

(3.1) |

(4.3) |

(2.1) |

(0.5) |

(1.8) |

25 |

90 |

110 |

61.0 |

15.0 |

1.3 |

(1) |

(3.5) |

(4.3) |

(2.4) |

(0.6) |

(2.9) |

32 |

110 |

150 |

66.0 |

19.0 |

3.0 |

(1 1/4) |

(4.3) |

(6.0) |

(2.6) |

(0.7) |

(6.6) |

40 |

115 |

150 |

70.0 |

25.0 |

3.2 |

(11/2) |

(4.5) |

(6.0) |

(2.8) |

(1.0) |

(7.0) |

50 |

125 |

174 |

93.5 |

32.0 |

3.8 |

(2) |

(4.9) |

(6.9) |

(3.7) |

(1.3) |

(8.4) |

| Materials | |

Body / Insert |

Carbon Steel ASTM A36 Gr. 1040, A276 Type 304, 316 |

Ball |

Stainless Steel ASTM A276 Type 410,304,316, A217 Gr. CA15, A351 Gr. CF8/ CF8M |

Stem / Gland |

Stainless Steel ASTM A276 Type 410/304/316 |

Seat |

PTFE / CFT / GFT |

Stem Washer / '0' Ring |

GFT / Viton Gr. B |

Stem Seal / Body Seal |

PTFE / Grafoil |

Lever |

Steel |

Surface Protection for Steel Valves |

Extemal Coating: Black Stoving Enamel |

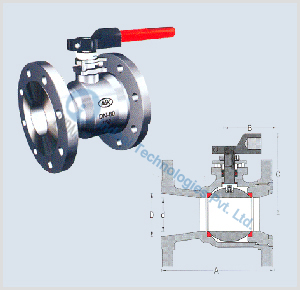

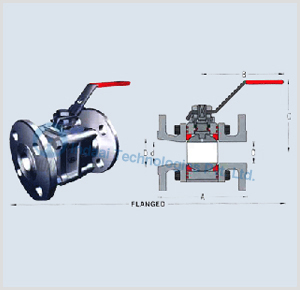

DESIGN sm : BS EN ISO 17292 (BS 5351) TESTING sm: EN 12266-1

Test Pressure in bar ( psi ) |

|||

Pressure rating |

Class 300 |

Class 150 |

Class 300 |

Hyd. Shell |

76 (1102) | 30 (435) | 76 (1102) |

Seat |

Refer Technical Data |

||

Air Seat |

6.9 (100) |

||

| Dimensions are in mm (inch) | ||||||||||||||||

SIZE mm (Inch) |

|

B |

C |

d |

D |

|

||||||||||

15 |

108 |

140 |

120 |

80 |

11 |

13 |

1.5 |

2.5 |

||||||||

(1/2) |

(4.3) |

(5.5) |

(4.7) |

(3.1) |

(0.4) |

(0.5) |

(3.3) |

(5.5) |

||||||||

20 |

117 |

152 |

145 |

85 |

13 |

20 |

1.B |

3.5 |

||||||||

(3/4) |

(4.6) |

(6.0) |

(5.7) |

(3.3) |

(0.5) |

(0.8) |

(4.0) |

(7.7) |

||||||||

25 |

127 |

165 |

145 |

90 |

20 |

25 |

2.6 |

4.5 |

||||||||

(1) |

(5.0) |

(6.5) |

(5.7) |

(3.5) |

(0.8) |

(1.0) |

(5.7) |

(9.9) |

||||||||

32 |

140 |

178 |

175 |

105 |

25 |

32 |

3.1 |

7.2 |

||||||||

(11/4) |

(5.5) |

(7.0) |

(6.9) |

(4.1) |

(1.0) |

(1.3) |

(6.8) |

(15.9) |

||||||||

40 |

165 |

190 |

175 |

110 |

32 |

38 |

4.5 |

9.0 |

||||||||

(11/2) |

(6.5) |

(7.5) |

(6.9) |

(4.3) |

(1.3) |

(1.5) |

(9.9) |

(19.8) |

||||||||

50 |

178 |

216 |

300 |

135 |

38 |

50 |

7.6 |

11.0 |

||||||||

(2) |

(7.0) |

(8.5) |

(11.8) |

(5.3) |

(1.5) |

(2.0) |

(16.8) |

(24.3) |

||||||||

65 |

190 |

241 |

475 |

155 |

50 |

64 |

9.8 |

16.2 |

||||||||

(21/2) |

(7.5) |

(9.5) |

(18.7) |

(6.1) |

(2.0) |

(2.5) |

(21.6) |

(35.7) |

||||||||

80 |

203 |

283 |

475 |

170 |

58 |

76 |

15.3 |

24.4 |

||||||||

(3) |

(8.0) |

(11.1 ) |

(18.7) |

(6.7) |

(2.3) |

(3.0) |

(33.7) |

(53.8) |

||||||||

100 |

229 |

305 |

575 |

205 |

76 |

98 |

22.5 |

38.0 |

||||||||

(4) |

(9.0) |

(12.0) |

(22.6) |

(8.1) |

(3.0) |

(3.9) |

(49.6) |

(83.8) |

||||||||

150 |

267 |

403 |

775 |

* |

98 |

152 |

38.0 |

68.5 |

||||||||

(6) |

(10.5) |

(15.9) |

(30.5) |

* |

(3.9) |

(6.0) |

(83.8) |

(151.0) |

||||||||

200 |

292 |

419 |

* |

* |

144 |

203 |

67.5 |

140.0 |

||||||||

(8) |

(11.5) |

(16.5) |

* |

* |

(5.7) |

(8.0) |

(148.8) |

(308.6) |

||||||||

250 |

330 |

457 |

* |

* |

187 |

250 |

113.5 |

173.0 |

||||||||

(10) |

(13.0) |

(18.0) |

* |

* |

(7.4) |

(9.8) |

(250.2) |

(381.4) |

||||||||

Materials |

|

Body / Insert |

Carbon Steel ASTM A216 Gr. WCB, A352 Gr.LCB, Stainless Steel ASTM A351 Gr. CF8/ CF8M / CF3 / CF3M / CN7M / Duplex |

Ball |

Stainless Steel ASTM A276 Type 410/304/316, ASTM A217 Gr.CA 15, ASTM A351 Gr. CF8/ CF8M / CN7M / Duplex |

Stem / Gland |

Stainless Steel ASTM A276 Type 410/304/316/ Duplex |

Seat |

PTFE / CFT / GFT / DELRIN / NYLON / PEEK / METAL |

Stem Washer / '0' Ring |

GFT / Viton B |

Stem Seal / Body Seal |

PTFE / Grafoil |

Lever |

Steel |

Surface Protection for Steel Valves |

Base phosphating. Additional Extemal Coating: Smoke Grey Synthetic Enamel |

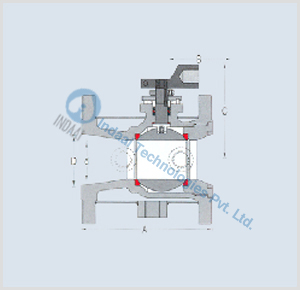

Test Pressure in bar (psi) |

||

Pressure rating |

Class 150 |

Class 300 |

Hyd. Shell |

30 (435) |

76 (1102) |

Seat |

REFER TECHNiCAl DATA |

|

Air Seat |

6.9 (100) |

|

SIZE mm (Inch) |

|

|

C |

d RB |

D RB & FB |

|

|||||||||||||||||||||||||||||||||||

15 X 25 |

108 |

140 |

120 |

120 |

120 |

120 |

80 |

11 |

13 |

2.3 |

2J |

3.2 |

3.6 |

||||||||||||||||||||||||||||

(1/2 x 1) |

(4.3) |

(5.5) |

(4.7) |

(4.7) |

(4.7) |

(4.7) |

(3.1) |

(0.4) |

(0.5) |

(5.1) |

(6.0) |

(7.1) |

(7.9) |

||||||||||||||||||||||||||||

20 x 32 |

117 |

152 |

120 |

145 |

120 |

145 |

85 |

13 |

20 |

2J |

4.0 |

4.0 |

4.5 |

||||||||||||||||||||||||||||

(3/4 x 1 1/4) |

(4.6) |

(6.0) |

(4.7) |

(5.7) |

(4.7) |

(5.7) |

(3.3) |

(0.5) |

(0.8) |

(6.0) |

(8.8) |

(8.8) |

(9.9) |

||||||||||||||||||||||||||||

25 x 40 |

127 |

165 |

145 |

145 |

145 |

145 |

90 |

20 |

25 |

5.4 |

6.3 |

6.3 |

6.7 |

||||||||||||||||||||||||||||

(1 x 11/2) |

(5.0) |

(6.5) |

(5.7) |

(5.7) |

(5.7) |

(5.7) |

(3.5) |

(0.8) |

(to) |

(11.9) |

(13.9) |

(13.9) |

(14.8) |

||||||||||||||||||||||||||||

32x50 |

140 |

178 |

145 |

175 |

145 |

175 |

105 |

25 |

32 |

8.1 |

9.0 |

9.0 |

10.0 |

||||||||||||||||||||||||||||

(1 1/4 x 2) |

(5.5) |

(7.0) |

(5.7) |

(6.9) |

(5]) |

(6.9) |

(4.1) |

(1.0) |

(1.3) |

(17.9) |

(19.8) |

(19.8) |

(22.0) |

||||||||||||||||||||||||||||

40 x 65 |

165 |

190 |

175 |

175 |

175 |

175 |

110 |

32 |

38 |

9.0 |

10.0 |

10.3 |

10.8 |

||||||||||||||||||||||||||||

(1 1/2 x 2 1/2) |

(6.5) |

(7.5) |

(6.9) |

(6.9) |

(6.9) |

(6.9) |

(4.3) |

(1.3 ) |

(1.5) |

(19.8) |

(22.0) |

(22.7) |

(23.8) |

||||||||||||||||||||||||||||

50 x 80 |

178 |

216 |

175 |

300 |

175 |

300 |

135 |

38 |

50 |

10.8 |

14.8 |

16.2 |

18.0 |

||||||||||||||||||||||||||||

(2 x 3) |

(7.0) |

(8.5) |

(6.9) |

(11.8) |

(6.9) |

(11.8) |

(5.3) |

(1.5) |

(2.0) |

(23.8) |

(32.6) |

(35.7) |

(39.7) |

||||||||||||||||||||||||||||

65 x 100 |

190 |

241 |

300 |

475 |

300 |

475 |

155 |

50 |

64 |

16.2 |

17.5 |

23.5 |

25.2 |

||||||||||||||||||||||||||||

(2 1/2 x 4) |

(7.5) |

(9.5) |

(11.8) |

(18.7) |

(11.8) |

(18.7) |

(6.1) |

(2.0) |

(2.5) |

(35.7) |

(38.6) |

(51.8) |

(55.6) |

||||||||||||||||||||||||||||

80 x 150 |

203 |

283 |

475 |

475 |

475 |

475 |

170 |

58 |

76 |

32.0 |

36.0 |

38.0 |

40.0 |

||||||||||||||||||||||||||||

(3 x 6) |

(8.0) |

(11.1) |

(18.7) |

(18.7) |

(18.7) |

(18.7) |

(6.7) |

(2.3) |

(3.0) |

(70.5) |

(79.4) |

(83.8) |

(88.2) |

||||||||||||||||||||||||||||

100 x 150 |

229 |

305 |

475 |

575 |

475 |

575 |

205 |

76 |

98 |

54.0 |

. |

72.0 |

|||||||||||||||||||||||||||||

(4 x 6) |

(9.0) |

(12.0) |

(18.7) |

(22.6) |

(18.7) |

(22.6) |

(8.1) |

(3.0) |

(3.9) |

. |

(119.0) |

. |

(158.7) |

||||||||||||||||||||||||||||

150 x 250 |

267 |

403 |

575 |

775 |

775 |

* |

* |

98 |

152 |

108.0 |

135.0 |

||||||||||||||||||||||||||||||

(6 x 10) |

(10.5) |

(15.9) |

(22.6) |

(30.5) |

(30.5) |

* |

* |

(3.9) |

(6.0) |

(238.1) |

. |

(297.6) |

|||||||||||||||||||||||||||||

200 x 300 |

292 |

419 |

775 |

* |

* |

* |

* |

144 |

203 |

145.0 |

288.0 |

||||||||||||||||||||||||||||||

(8 x 12) |

(11.5) |

(16.5) |

(30.5) |

* |

* |

* |

* |

(5.7) |

(8.0) |

(319.7) |

. |

(634.9) |

|||||||||||||||||||||||||||||

250 x 350 |

330 |

457 |

* |

* |

* |

* |

* |

187 |

250 |

. |

338.0 |

||||||||||||||||||||||||||||||

(10 x 14) |

(13.0) |

(18.0) |

* |

* |

* |

* |

* |

(7.4) |

(9.8) |

(745.2) |

|||||||||||||||||||||||||||||||

Material |

|

Body / Insert |

Carbon Steel ASTM A216 Gr. WCB, A352 Gr. LCB, Stainless Steel ASTM A351 Gr. CF8/ CF8M / CF3 / CF3M / CN7M / Duplex |

Ball |

Stainless Steel ASTM A217 Gr. CA15, ASTM A351 Gr. CF8/ CF8M / CN7M / Duplex |

Stem / Gland |

Stainless Steel ASTM A276 Type 410/304/316/ A.20 / Duplex |

Seat |

PTFE / CFT / GFT / DELRIN / NYLON / PEEK / METAL |

Stem Washer / '0' Ring |

GFT / Viton B |

Stem Seal |

PTFE / Grafoil |

Body Seal |

PTFE / Grafoil / SPIRAL WOUND GASKET |

Gland Nut |

Steel (Plated) |

Lever |

Steel |

Surface Protection for Steel Valves |

Base phosphating. Additional External Coating: Smoke Grey Synthetic Enamel |

Nett in Kg (lbs.) approx(without obligation) Worm Gear Operated *Stem Seal PTFE for non fire Safe Valves *Valves can be supplied to suit ASME / BS / DIN FLANGES. * Valves can be supplied with Pad-lock ,Electric, Pneumatic or Gear actuators and accessories like Limit switch, solenoid valve. * Actuator Bracket Mounting as per ISO 5211. *Please specify Working Pressure, Temperature & service conditions. * Cavity free ( Pocketless) also available. * Other materials not mentioned above available on request.

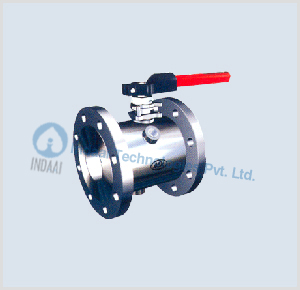

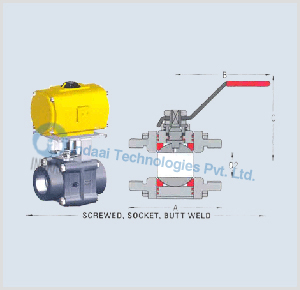

Test Pressure in bar (psi) |

||||

FLANGED |

SE, SWE & BWE |

|||

Pressure rating |

Class 150 |

Class 300 |

Class 600 |

Class 800 |

| Hyd. Shell | 30 (435) | 76 (1102) | 150 (2176) | 207 (3002) |

| Seat | REFER TECHNiCAl DATA |

REFER TECHNiCAl DATA |

||

Air Seat |

6.9 (100) |

6.9 (100) |

||

Dimensions are in mm (inch) |

Flaged, SE,SWE & BWE | |||||||||||||||||||||||||||||||||||||||||||||||||||

| SIZE mm (Inch) |

|

|

C |

d RB |

D RB & FB |

|

|

|||||||||||||||||||||||||||||||||||||||||||||

10 |

- |

- |

64 |

64 |

120 |

120 |

80 |

- |

11 |

11 |

11 |

- |

- |

- |

- |

0.7 |

0.7 |

|||||||||||||||||||||||||||||||||||

(3/8) |

- |

- |

(2.5) |

(2.5) |

(4.7) |

(4.7) |

(3.1) |

- |

(0.4) |

(0.4) |

(0.4) |

- |

- |

- |

- |

(1.5) |

(1.5) |

|||||||||||||||||||||||||||||||||||

15 |

108 |

140 |

64 |

64 |

120 |

120 |

80 |

11 |

13 |

11 |

13 |

1.5 |

1.7 |

2.4 |

2.7 |

0.7 |

0.8 |

|||||||||||||||||||||||||||||||||||

(1/2) |

(4.3) |

(5.5) |

(2.5) |

(2.5) |

(4.7) |

(4.7) |

(3.1) |

(0.4) |

(0.5) |

(0.4) |

(0.5) |

(3.3) |

(3.7) |

(5.3) |

(5.3) |

(1.5) |

(1.5) |

|||||||||||||||||||||||||||||||||||

20 |

117 |

152 |

70 |

75 |

120 |

145 |

85 |

13 |

20 |

13 |

20 |

1.7 |

2.5 |

3.3 |

3.8 |

0.9 |

1.5 |

|||||||||||||||||||||||||||||||||||

(3/4) |

(4.6) |

(6.0) |

(2.8) |

(3.0) |

(4.7) |

(5.7) |

(3.3) |

(0.5) |

(0.8) |

(0.5) |

(0.8) |

(3.7) |

(5.5) |

(7.3) |

(8.4) |

(2.0) |

(3.3) |

|||||||||||||||||||||||||||||||||||

25 |

127 |

165 |

88 |

88 |

145 |

145 |

90 |

20 |

25 |

20 |

25 |

2.6 |

2.9 |

4.3 |

4.9 |

1.6 |

2.0 |

|||||||||||||||||||||||||||||||||||

(1) |

(5.0) |

(6.5) |

(3.5) |

(3.5) |

(5.7) |

(5.7) |

(3.5) |

(0.8) |

(1.0) |

(0.8) |

(1.0) |

(5.7) |

(6.4) |

(9.5) |

(10.8) |

(3.5) |

(4.4) |

|||||||||||||||||||||||||||||||||||

32 |

140 |

178 |

105 |

105 |

145 |

175 |

105 |

25 |

32 |

25 |

32 |

3.8 |

4.2 |

5.1 |

6.8 |

2.2 |

3.1 |

|||||||||||||||||||||||||||||||||||

(11/4) |

(5.5) |

(7.0) |

(4.1) |

(1.4) |

(5.7) |

(6.9) |

(1.4) |

(1.0) |

(1.3) |

(1.0) |

(1.3) |

(8.4) |

(9.3) |

(11.2) |

(15.0) |

(4.8) |

(6.8) |

|||||||||||||||||||||||||||||||||||

40 |

165 |

190 |

114 |

114 |

175 |

175 |

110 |

32 |

38 |

32 |

38 |

5.7 |

6.5 |

9.3 |

10.2 |

3.5 |

4.7 |

|||||||||||||||||||||||||||||||||||

(11/2) |

(6.5) |

(7.5) |

(4.5) |

(4.5) |

(6.9) |

(6.9) |

(4.3) |

(1.3) |

(1.5) |

(1.3) |

(1.5) |

(12.6) |

(14.3) |

(20.5) |

(22.5) |

(7.7) |

(10.4) |

|||||||||||||||||||||||||||||||||||

50 |

178 |

216 |

130 |

145 |

175 |

300 |

135 |

38 |

50 |

38 |

50 |

8.2 |

9.5 |

11.2 |

14.5 |

4.9 |

8.5 |

|||||||||||||||||||||||||||||||||||

(2) |

(7.0) |

(8.5) |

(5.1) |

(5.7) |

(6.9) |

(11.8) |

(5.3) |

(1.5) |

(2.0) |

(1.5) |

(2.0) |

(18.1) |

(21.0) |

(24.7) |

(32.0) |

(10.8) |

(18.7) |

|||||||||||||||||||||||||||||||||||

Materials |

|

Body / End piece |

Forged Carbon Steel ASTM A 105/ Cast Carbon Steel ASTM A216 Gr. WCB / Stainless Steel ASTM A 182 Gr. F304 / F316, ASTM A351 Gr. CF8/ CF8M / CF3 / CF3M / CN7M / Duplex |

Ball / Stem |

Stainless Steel ASTM A276 Type 410 / 304 / 316 / A20 / Duplex |

Seat |

PTFE / CFT / GFT / DELRIN / NYLON / PEEK / METAL |

Stem Washer / '0' Ring |

GFT / Viton B |

Stem Seal/Body Seal |

PTFE / Grafoil |

Lever |

Steel with PVC Sleeve |

Body Studs / Nuts |

ASTM A193 Gr. B7/ ASTM A194 Gr. 2H |

Surface Protection for Carbon Steel Valves |

Base Phosphating. Additional External Coating: Smoke Grey Synthetic Enamel |