Mobile No.

+91 97663 36366

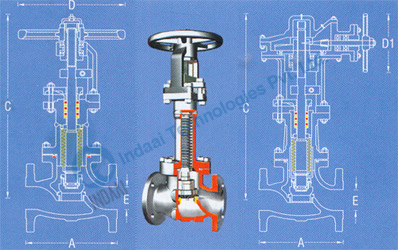

Test Pressure in bar (psi) |

||

Pressure rating |

Class 300 |

Class 150 |

| Hyd. Shell | 31 |

78 |

| Seat | 23 |

58 |

Air Seat |

7 |

|

| Dimensions are in mm (inch) | ||||||||||||||||||||||

| SIZE | A CLASS |

|

|

D1 |

E |

|

||||||||||||||||

| mm | 150 |

300 |

||||||||||||||||||||

15 |

108 |

152 |

322 |

320 |

150 |

150 |

15 |

5.0 |

8.0 |

|||||||||||||

20 |

117 |

178 |

322 |

320 |

150 |

150 |

19 |

6.0 |

9.0 |

|||||||||||||

25 |

127 |

203 |

353 |

357 |

200 |

200 |

25 |

8.0 |

12.0 |

|||||||||||||

32 |

140 |

216 |

380 |

390 |

200 |

200 |

32 |

11 |

15 |

|||||||||||||

40 |

165 |

229 |

460 |

458 |

250 |

250 |

38 |

16 |

27 |

|||||||||||||

50 |

203 |

267 |

498 |

501 |

250 |

250 |

50 |

19 |

36 |

|||||||||||||

65 |

216 |

292 |

530 |

540 |

300 |

300 |

65 |

27 |

43 |

|||||||||||||

80 |

241 |

318 |

635 |

641 |

350 |

350 |

76 |

43 |

51 |

|||||||||||||

100 |

292 |

356 |

737 |

750 |

350 |

450 |

102 |

69 |

72 |

|||||||||||||

150 |

406 |

444 |

850 |

950 |

300 |

152 |

125 |

142 |

||||||||||||||

200 |

495 |

559 |

1000 |

1020 |

300 |

203 |

142 |

175 |

||||||||||||||

250 |

622 |

622 |

1120 |

1130 |

600 |

254 |

195 |

215 |

||||||||||||||

300 |

698 |

711 |

1680 |

1730 |

600 |

305 |

240 |

270 |

||||||||||||||

Materials |

|

Body / Bonnet / Stuffing Box |

Carbon Steel ASTM A216 Gr. WCB, Stainless Steel ASTM 351 Gr. CF8 / CF8M |

Yoke / Gland Flanges |

Carbon Steel ASTM A216 Gr. WCB |

Seat Ring / Disc Plug Type / Disc Nut |

Stainless Steel ASTM A276 Type 304 / 316 / 410 |

Body Seal |

PTFE / S.W.G. 316 |

Body Stud / Gland Stud |

ASTM A193 Gr. B7 / B8 / B8M |

Gland Packing |

PTFE |

Gland / Spindle / Split Washer |

Stainless Steel ASTM A276 Type 304 / 316 / 410 |

Hand Wheel / Indicator |

S.G.IRON |

Bellow |

Stainless Steel ASTM A276 Type 316 Ti / 321 |

Surface Protection for Carbon Steel Valves |

Prime Coat : Chlorine free with modified alkyd resin, unobjectionable in physiological & toxicological respects, with additional external coating of machine varnish light blue. |

1) Net in Kg. (Ibs) approx. (without obligation) * Valves can be supplied to suitASMEI BS I DIN Flanges.* Ductile Iron only for Wafer check Valves. * Cover & Guide plate applicable for Non Slam only. . Spring applicable for Wafer Check Valves from Sizes 50mm (2") to 300mm (12'') & Non Slam only.* Dual plate Valves can be supplied with soft seating arrangement on request. * Please Specify Working Pressure, Temperature & Service conditions. * Other materials not mentioned above available on request.

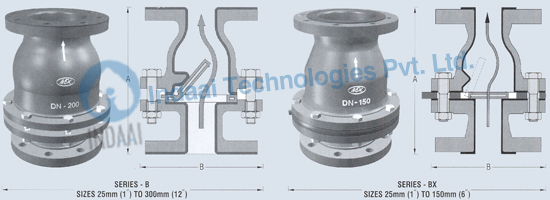

Test Pressure in bar (psi) |

|

Pressure Rating |

PN7 |

Hyd. Shell |

11 (159) |

Seat |

7 (101) |

| Dimensions are in mm (inch) | |||||||||

SERIES - B |

SERIES - BX |

||||||||

SIZE |

A

|

B |

Wt 1 |

A |

B |

Wt 1 |

|||

mm (inch) |

Unlined |

Rubber Lined |

Unlined |

Rubber Lined |

|||||

25 (1) |

144 (5.7) |

150 (5.9) |

124 (4.9) |

4.0 (8.8) |

150 (5.9) |

157 (6.2) |

126 (5.0) |

5.5 (12) |

|

40 (1 1/2) |

174 (6.9) |

180 (7.1) |

144 (5.7) |

7.0 (15) |

180 (7.1) |

186 (7.3) |

149 (5.9) |

9.5 (21) |

|

50 (2) |

194 (7.6) |

200 (7.9) |

166 (6.5) |

8.5 (19) |

200 (7.9) |

206 (8.1) |

163 (6.4) |

11.0 (24) |

|

65 (2 1/2) |

234 (9.2) |

240 (9.4) |

220 (8.7) |

14 (31) |

240 (9.4) |

244 (9.6) |

185 (7.3) |

17.5 (39) |

|

80 (3) |

254 (10.0) |

260 (10.2) |

220 (8.7) |

20 (44) |

260 (10.2) |

266 (10.5) |

218 (8.6) |

21.5 (47) |

|

100 (4) |

292 (11.5) |

300 (11.8) |

270 (10.6) |

34 (75) |

350 (13.8) |

358 (14.1) |

295 (11.6) |

37.5 (83) |

|

150 (6) |

392 (15.4) |

400 (15.7) |

322 (12.7) |

56 (123) |

400 (15.7) |

406 (16.0) |

325 (12.8) |

64.5 (142) |

|

200 (8) |

492 (19.4) |

500 (19.7) |

396 (15.6) |

103 (227) |

- |

- |

- |

- |

|

250 (10) |

590 (23.2) |

600 (23.6) |

500 (19.7) |

190 (419) |

- |

- |

- |

- |

|

300 (12) |

690 (27.2) |

700 (27.6) |

554 (21.8) |

310 (683) |

- |

- |

- |

- |

|

| Materials | |

Body / End piece |

Cast Iron ASTM A126 Class C / EN1561 No. EN-JL1040 / ASTM A216 Gr. WCB |

Disc |

Steel plate duly rubber lined. (Grade according to working condition) |

Connecting bolts / nuts |

Steel ASTM A307 Gr. A / ASTM A563 Gr. A |

Surface Protection for |

Prime Coat : Chlorine free with modified alkyd resin unobjectionable in physiological and toxicolgical respects. |

Valves |

Additional external coating : Stoving enamel |

1) Net in Kg. (Ibs) approx. (without obligation) 2) Face to Face dimension 'A for RIL Valves DIN 3202 F6 for Series - B only & others as manufacturer standard. * Valves can be supplied to suit ASME / BS / DIN Flanges. *Please Specify Working Pressure, Temperature & Service conditions. * Other materials not mentioned above available on request.