Mobile No.

+91 97663 36366

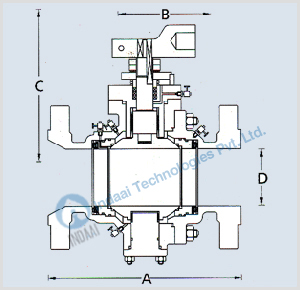

| Dimensions are in mm (inch) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size mm |

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 |

178 |

216 |

292 |

184 |

307 |

184 |

307 |

240 |

602 |

36/30 |

49 |

11 |

15 |

15 |

20 |

19 |

25 |

|||||||||||||||||||||||||||||||||||||||||||

(2) |

(7.0) |

(8.5) |

(11.5) |

(7.2) |

(12.1) |

(7.2) |

(12.1) |

(9.4) |

(23.7) |

(1.4/1.2) |

(1.9) |

(24) |

(33) |

(33) |

(44) |

(42) |

(55) |

|||||||||||||||||||||||||||||||||||||||||||

65 |

190 |

241 |

330 |

307 |

482 |

307 |

502 |

602 |

602 |

49/41 |

62 |

18 |

22 |

26 |

34 |

36 |

52 |

|||||||||||||||||||||||||||||||||||||||||||

(21/2) |

(7.5) |

(9.5) |

(13.0) |

(12.1) |

(19.0) |

(12.1) |

(19.8) |

(23.7) |

(23.7) |

(1.9/1.6) |

(2.4) |

(40) |

(49) |

(57) |

(75) |

(79) |

(115) |

|||||||||||||||||||||||||||||||||||||||||||

80 |

203 |

283 |

356 |

482 |

482 |

502 |

602 |

602 |

625 |

55/49 |

75 |

25 |

30 |

38 |

43 |

68 |

90 |

|||||||||||||||||||||||||||||||||||||||||||

(3) |

(8.0) |

(11.1 ) |

(14.0) |

(19.0) |

(19.0) |

(19.8) |

(23.7) |

(23.7) |

(24.6) |

(2.2/1.9) |

(3.0) |

(55) |

(66) |

(84) |

(95) |

(150) |

(198) |

|||||||||||||||||||||||||||||||||||||||||||

100 |

229 |

305 |

432 |

482 |

602 |

602 |

* |

625 |

* |

74162 |

98 |

34 |

42 |

54 |

76 |

105 |

140 |

|||||||||||||||||||||||||||||||||||||||||||

(4) |

(9.0) |

(12.0) |

(17.0) |

(19.0) |

(23.7) |

(23.7) |

* |

(24.6) |

* |

(2.9/2.4) |

(3.9) |

(75) |

(93) |

(119) |

(168) |

(232) |

(309) |

|||||||||||||||||||||||||||||||||||||||||||

150 |

2672) |

403 |

559 |

800 |

* |

* |

* |

* |

* |

98174 |

148 |

52 |

90 |

94 |

140 |

190 |

262 |

|||||||||||||||||||||||||||||||||||||||||||

(6) |

(10.5) |

(15.9) |

(22.0) |

(31.5) |

* |

* |

* |

* |

* |

(3.9/2.9) |

(5.8) |

(115) |

(198) |

(207) |

(309) |

(419) |

(578) |

|||||||||||||||||||||||||||||||||||||||||||

200 |

2922) |

502 |

660 |

* |

* |

* |

* |

* |

* |

144/1 00 |

198/1943) |

100 |

170 |

156 |

225 |

340 |

412 |

|||||||||||||||||||||||||||||||||||||||||||

(8) |

(10.5) |

(19.8) |

(26.0) |

* |

* |

* |

* |

* |

* |

(5.7/3.9) |

(7.817.6) |

(221) |

(375) |

(345) |

(496) |

(750) |

(908) |

|||||||||||||||||||||||||||||||||||||||||||

250 |

3302) |

568 |

787 |

* |

* |

* |

* |

* |

* |

186/151 |

245/2413) |

190 |

265 |

250 |

345 |

490 |

635 |

|||||||||||||||||||||||||||||||||||||||||||

(10) |

(13.0) |

(22.4) |

(31.0) |

* |

* |

* |

* |

* |

* |

(7.3/5.9) |

(9.6/9.5) |

(419) |

(584) |

(551) |

(761) |

(1080) |

(1400) |

|||||||||||||||||||||||||||||||||||||||||||

300 |

3562) |

648 |

838 |

* |

* |

* |

* |

* |

* |

227/202 |

295/2913) |

290 |

390 |

400 |

490 |

800 |

960 |

|||||||||||||||||||||||||||||||||||||||||||

(12) |

(14.0) |

(25.5) |

(33.0) |

* |

* |

* |

* |

* |

* |

(8.9/8.0) |

(11.6/11.5) |

(639) |

(860) |

(882) |

(1080) |

(1764) |

(2116) |

|||||||||||||||||||||||||||||||||||||||||||

350 |

686 |

762 |

889 |

* |

* |

* |

* |

* |

* |

266/230 |

325/3183) |

430 |

475 |

605 |

665 |

1045 |

1325 |

|||||||||||||||||||||||||||||||||||||||||||

(14) |

(27.0) |

(30.0) |

(35.0) |

* |

* |

* |

* |

* |

* |

(10.4/9.1) |

(12.8/12.5) |

(948) |

(1047) |

(1334) |

(1466) |

(2304) |

(2921) |

|||||||||||||||||||||||||||||||||||||||||||

400 |

762 |

838 |

991 |

* |

* |

* |

* |

* |

* |

305/250 |

375/3653) |

560 |

775 |

745 |

925 |

1520 |

1785 |

|||||||||||||||||||||||||||||||||||||||||||

(16) |

(30.0) |

(33.0) |

(39.0) |

* |

* |

* |

* |

* |

* |

(12.0/9.8) |

(14.8/14.4) |

(1235) |

(1709) |

(1642) |

(2039) |

(2756) |

(3935) |

|||||||||||||||||||||||||||||||||||||||||||

450 |

864 |

914 |

1093 |

* |

* |

* |

* |

* |

* |

335/305 |

430/421 |

840 |

925 |

995 |

1125 |

1860 |

2010 |

|||||||||||||||||||||||||||||||||||||||||||

(18) |

(34.0) |

(36.0) |

(43.0) |

* |

* |

* |

* |

* |

* |

(13.2/12.0) |

(16.9/16.6) |

(1852) |

(2039) |

(2194) |

(2480) |

(4101) |

(4431) |

|||||||||||||||||||||||||||||||||||||||||||

500 |

915 |

991 |

1194 |

* |

* |

* |

* |

* |

* |

375/335 |

475/453 |

960 |

1015 |

1335 |

1555 |

2150 |

2300 |

|||||||||||||||||||||||||||||||||||||||||||

(20) |

(36.0) |

(39.0) |

(47.0) |

* |

* |

* |

* |

* |

* |

(14.8/13.2) |

(18.7/17.8) |

(2116) |

(2238) |

(2943) |

(3428) |

(4740) |

(5071) |

|||||||||||||||||||||||||||||||||||||||||||

600 |

1067 |

1143 |

1397 |

* |

* |

* |

* |

* |

* |

487 |

589 |

1025 |

2050 |

2450 |

2800 |

3250 |

3900 |

|||||||||||||||||||||||||||||||||||||||||||

(24) |

(42.00) |

(45.0) |

(55.0) |

* |

* |

* |

* |

* |

* |

(19.2) |

(23.2) |

(2260) |

(4520) |

(5401) |

(6173) |

(7165) |

(8568) |

|||||||||||||||||||||||||||||||||||||||||||

750 |

1295 |

1397 |

* |

* |

* |

* |

- |

633 |

735 |

2000 |

3200 |

3020 |

4100 |

|||||||||||||||||||||||||||||||||||||||||||||||

(30) |

(51.0) |

(55.0) |

|

* |

* |

* |

* |

|

|

(24.9) |

(28.9) |

(4409) |

(7055) |

(6658) |

(9039) |

|

|

|||||||||||||||||||||||||||||||||||||||||||

| Dimensions are in mm (inch) | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Size mm (inch) |

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||

50 |

368 |

368 |

550 |

550 |

247 |

450 |

36/30 |

49 |

36/30 |

49 |

38 |

52 |

38 |

52 |

||||||||||||||||||||||||||||||||||||

(2) |

(14.5) |

(14.5) |

(21.7) |

(21.7) |

(9.7) |

(17.7) |

(1.4/1.2) |

(1.9) |

(1.4/1.2) |

(1.9) |

(84) |

(115) |

(84) |

(115) |

||||||||||||||||||||||||||||||||||||

65 |

419 |

419 |

550 |

550 |

425 |

475 |

49/41 |

62 |

49/41 |

62 |

75 |

90 |

75 |

90 |

||||||||||||||||||||||||||||||||||||

(21/2) |

(16.5) |

(16.5) |

(21.7) |

(21.7) |

(16.7) |

(18.7) |

(1.9/1.6) |

(2.4) |

(1.9/1.6) |

(2.4) |

(165) |

(198) |

(165) |

(198) |

||||||||||||||||||||||||||||||||||||

80 |

381 |

470 |

* |

* |

450 |

575 |

55/49 |

74 |

55/49 |

74 |

105 |

145 |

135 |

220 |

||||||||||||||||||||||||||||||||||||

(3) |

(15.0) |

(18.5) |

* |

* |

(17.7) |

(22.6) |

(2.211.9) |

(2.9) |

(2.211.9) |

(2.9) |

(232) |

(320) |

(298) |

(485) |

||||||||||||||||||||||||||||||||||||

100 |

457 |

546 |

* |

* |

457 |

600 |

74/62 |

100 |

74/62 |

100 |

200 |

250 |

300 |

355 |

||||||||||||||||||||||||||||||||||||

(4) |

(18.0) |

(21.5) |

* |

* |

(18.0) |

(23.6) |

(2.9/2.4) |

(3.9j |

(2.9/2.4) |

(3.9) |

(441) |

(551) |

(661) |

(783) |

||||||||||||||||||||||||||||||||||||

150 |

610 |

705 |

* |

* |

575 |

700 |

98/74 |

150 |

98/74 |

144 |

315 |

395 |

355 |

450 |

||||||||||||||||||||||||||||||||||||

(6) |

(24.0) |

(27.8) |

* |

* |

(22.6) |

(27.6) |

(3.9/2.9) |

(5.9) |

(3.9/2.9) |

(5.7) |

(695) |

(871) |

(783) |

(992) |

||||||||||||||||||||||||||||||||||||

200 |

737 |

832 |

* |

* |

680 |

800 |

144/100 |

201 |

144/100 |

192 |

580 |

685 |

650 |

775 |

||||||||||||||||||||||||||||||||||||

(8) |

(29.0) |

(32.8) |

* |

* |

(26.8) |

(31.5) |

(5.7/3.9) |

(7.9) |

(5.7/3.9) |

(7.6) |

(1279) |

(1510) |

(1433) |

(1708) |

||||||||||||||||||||||||||||||||||||

250 |

838 |

991 |

* |

* |

775 |

900 |

186/151 |

252 |

186/151 |

239 |

820 |

980 |

890 |

1125 |

||||||||||||||||||||||||||||||||||||

(10) |

(33.0) |

(39.0) |

* |

* |

(30.5) |

(35.4) |

(7.3/5.9) |

(9.9) |

(7.3/5.9) |

(9.4) |

(1808) |

(2160) |

(1962) |

(2480) |

||||||||||||||||||||||||||||||||||||

300 |

965 |

1130 |

* |

* |

850 |

1000 |

227/202 |

303 |

227/202 |

287 |

1220 |

1375 |

1250 |

1580 |

||||||||||||||||||||||||||||||||||||

(12) |

(38.0) |

(44.5) |

* |

* |

(33.5) |

(39.4) |

(8.9/8.0) |

(11.9) |

(8.9/8.0) |

(11.3) |

(2690) |

(3031) |

(2756) |

(3483) |

||||||||||||||||||||||||||||||||||||

350 |

1050 |

|

* |

* |

975 |

1125 |

266/230 |

322 |

- |

- |

1490 |

1650 |

- |

- |

||||||||||||||||||||||||||||||||||||

(14) |

(41.3) |

- |

* |

* |

(38.4) |

(44.3) |

(10.4/9.1 ) |

(12.7) |

- |

- |

(3284) |

(3638) |

- |

- |

||||||||||||||||||||||||||||||||||||

400 |

1130 |

|

* |

* |

1200 |

1325 |

305/250 |

373 |

- |

- |

1620 |

1880 |

- |

- |

||||||||||||||||||||||||||||||||||||

(16) |

(44.5) |

- |

* |

* |

(47.2) |

(52.2) |

(12.0/9.8) |

(14.7) |

- |

- |

(3572) |

(4145) |

- |

- |

||||||||||||||||||||||||||||||||||||

1) Nett in kg. (lbs) approx, with flanged ends.(without obligation) 2) Long Pattern for Sealant injection System. 3) Dimension 'D' For Class 600 * For Dimensions 'c'refer sales drgs. * Flanged Ends according to ASME B16.5; other drilling on request.* Butt Weld Ends according to ASME B16.25 * Please Specify Working Pressure, Temperature & Service Conditon * VAlves can be supplied with padlock, Electric, pneumatic or Gear Actuators; other accessories like Limit Switch, Air FilterRegulator, Positioner etc.

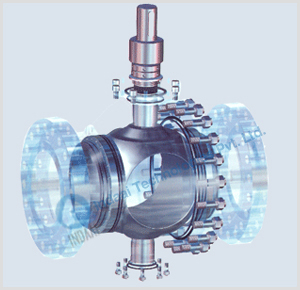

STANDARDS |

|

DESIGN : |

API6D, BS EN ISO 17292 (BS 5351), ASME B16.34 |

TESTING |

API6D, API 598, EN 12266-1, ASME B16.34, API 607/ 6FA |

MODELS |

|

'W'TR |

'W' Series Trunnion Mounted Reduced Bore |

'W'TF |

'W' Series Trunnion Mounted Full Bore |

'W'TMR |

'W' Series Trunnion Mounted Metal Seat Reduced Bore |

'W'TMF |

'W' Series Trunnion Mounted Metal Seat Full Bore |

| MATERIALS | |

| Body/ End Piece | Carbon Steel ASTM A216 Gr. WCB, A352 Gr. LCB, Stainless Steel ASTM A351 Gr.CF8 / CF8M / CN7M /Duplex |

| Ball | Carbon Steel ASTM A216 Gr. WCB+ ENP / Stainless Steel ASTM A217 Gr. CA 15/ ASTM A351 Gr. CF8/ CF8M / CN7M / Duplex |

| Stem / Trunnion | Stainless Steel ASTM A564 TYPE 630 (17-4PH) / UNS S31803 |

| Seat / Seat Insert | PTFE / RPTFE / DELRIN / NYLON / PEEK / METAL . |

| Metal Seat | Stainless Steel ASTM A276 Type 410 Hardened /ASTM A276 Type 316 Stellited |

| Seat Retainer | ASTM A276 Type 410 / A217 Gr. CA15 / A276 Type 316 / A351 Gr. CF8M |

| Coil Spring | INCONEL X-750 |

| '0' Ring | Viton Gr. B |

| Stem / Thrust Washer | RPTFE (GFT) |

| Body Seal | SPIRAL WOUND SS With Graphite filler |

| Stem Seal | Grafoil |

| Trunnion / Stuffing Box Seal | PTFE / Grafoil / SPIRAL WOUND SS With Graphite filler |

| Stuffing Box | Carbon Steel ASTM A216 Gr. WCB, A352 Gr. LCB, Stainless Steel ASTM A351 Gr. CF8/ CF8M / CN7M |

| Stuf. Box & Trunnion Bearing | SS Backed PTFE |

| Gland Nut | Stainless Steel |

| Body Stud / Nut | ASTM A 193 Gr. B7 / ASTM A 194 Gr. 2H |

| Surface Protection for Carbon Steel Valves | Prime coat: Chlorine free with modified alkyd resin unobjectionable in Physiological and Toxicological respects with additional external coating of Machine varnish Smoke Gray |

BS EN ISO 17292 (BS 5351) Seat Test Pressure in Bar.{psi) As Per The Material Shown Below

|

||||||

I |

II |

III |

I, II & III |

|||

Class 150 |

Class 300 |

Class 150 |

Class 300 |

Class 150 |

Class 300 |

Class 600 |

22 |

51 |

21 |

51 |

18 |

48 |

51 |

(319) |

(740) |

(305) |

(740) |

(261) |

(696) |

(740) |

| Materials | I) WCB, WC6, WC9, LCC, Duplex SS Materials II) CF3, CF8, CF3M, CF8M, CF8C, LCB III) CN7M, Hast-B, Hast-C |

|||||

API 6D / ASME B16.34 in Bar (psi) |

|||||

| Pressure rating | Class 150 |

Class 300 |

Class 600 |

Class 900 |

Class 1500 |

Shell |

30 |

78 |

153 |

229 |

380 |

(435) |

(1131) |

(2219) |

(3321) |

(5511) |

|

Seat |

22 |

56 |

112 |

169 |

281 |

(319) |

(812) |

(1624) |

(2451) |

(4075) |

|

Air Seat |

{ (102)7} |

||||

For BS EN ISO 17292 (BS 5351) Shell Test & Air Seat according to API 6D / ASME B16.34 .

Metal Seated Valves are tested for full rated pressure

Leakage Rate: Soft Seat: 100% Tight Shut Off, Metal Seat: Class V

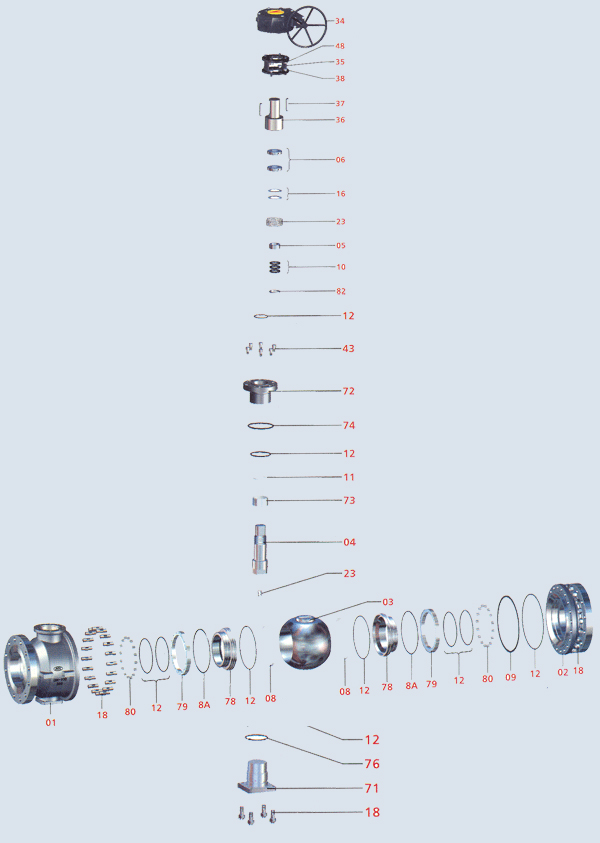

| No. | Part Name | No. | Part Name |

| 01 | BODY | 36 | ADAPTER |

| 02 | END PIECE | 37 | KEY |

| 03 | BALL | 38 | HEX. SCREW - STUFFING BOX TO BRACKET |

| 04 | STEM | 43 | HEX. SOC. HD. CAP SCREW BODY TO STUFFING BOX |

| 05 | GLAND | 48 | HEX. SCREW - BRACKET TO ACTUATOR |

| 06 | GLAND NUT | 71 | TRUNNION |

| 08 | SEAT | 72 | STUFFING BOX |

| 8A | BODY SEAL | 73 | STUFFING BOX BEARING |

| 10 | STEM SEAL | 74 | STUFFING BOX SEAL |

| 11 | STEM WASHER | 75 | TRUNNION BEARING |

| 12 | 'O'RING | 76 | TRUNNION SEAL |

| 16 | DISC SPRING BODY TO END PIECE |

77 | THRUST WASHER |

| 18 | STUD I NUT TRUNNION TO BODY STEM TO BALL |

78 | SEAT RETAINER |

| 23 | ANTISTATIC SPRING STUFFING BOX TO DISC SPRING |

79 | BACK UP RING |

| 34 | GEAR ACTUATOR | 80 | COIL SPRING |

| 35 | BRACKET | 82 | SUPPORT RING |