Mobile No.

+91 97663 36366

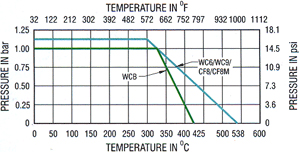

Test Pressure in bar (psi) |

||||

Pressure rating |

PN16 |

PN10 |

PN6 |

PN6 |

Hyd. Shell |

24 (348) |

15 (218) |

9 (131) |

6 (87) |

Seat |

17.6 (255) |

11 (160) |

6.6 (96) |

4.4 (64) |

Air Seat |

6.9 (100) |

6.6 (96) |

4.4 (64) |

|

Dimensions are in mm (inch) MODEL - 12 & 12L - PN16 RATING |

||||||||||||

SIZE mm (Inch) |

A |

B |

C |

d |

E |

F |

|

|||||

32/40 (11/4/11/2) |

33 (1.3) |

95 (3.7) |

65 (2.6) |

13 (0.5) |

30 (1.2) |

300 (11.8) |

4.0 (9) |

5.5 (12) |

||||

50 (2) |

43 (1.7) |

115 (4.5) |

75 (2.9) |

33.5 (1.3) |

30 (1.2) |

300 (11.8) |

4.5 (10) |

6.5 (14) |

||||

65 (21/2) |

46 (1.8) |

117 (4.6) |

85 (3.3) |

47 (1.9) |

30 (1.2) |

300 (11.8) |

5 (11) |

8.5 (19) |

||||

80 (3) |

46 (1.8) |

135 (5.3) |

90 (3.5) |

66 (2.6) |

30 (1.2) |

300 (11.8) |

5.5 (12) |

9 (20) |

||||

100 (4) |

52 (2.0) |

153 (6.0) |

118 (4.6) |

91.5 (3.6) |

30 (1.2) |

300 (11.8) |

7 (15) |

13 (29) |

||||

125 (5) |

56 (2.2) |

172 (6.8) |

135 (5.3) |

118 (4.6) |

30 (1.2) |

300 (11.8) |

8 (17) |

17 (37) |

||||

150 (6) |

56 (2.2) |

185 (7.3) |

148 (5.8) |

146 (5.7) |

30 (1.2) |

300 (11.8) |

9 (20) |

19 (42) |

||||

200 (8) |

60 (2.4) |

221 (8.7) |

175 (6.9) |

199 (7.8) |

170 (6.7) |

180 (7.1) |

28 (62) |

43 (95) |

||||

250 (10) |

68 (2.7) |

250 (9.8) |

210 (8.3) |

247 (9.7) |

170 (6.7) |

180 (7.1) |

34 (75) |

56 (123) |

||||

300 (12) |

78 (3.1) |

277 (10.9) |

250 (9.8) |

297 (11.7) |

200 (7.9) |

240 (9.4) |

51 (112) |

92 (209) |

||||

Dimensions are in mm (inch) MODEL - 44 & 44L - PN10 RATING |

||||||||||||

SIZE mm (Inch) |

A |

B |

C |

d |

E |

F |

|

|||||

200 (8) |

60 (2.4) |

221 (8.7) |

175(6.9) |

199 (7.8) |

170 (6.7) |

180 (7.1) |

28 (62) |

43 (95) |

||||

250 (10) |

68 (2.7) |

250 (9.8) |

210 (8.3) |

247 (9.7) |

170 (6.7) |

180 (7.1) |

34 (75) |

56 (123) |

||||

300 (12) |

78 (3.1) |

277 (10.9) |

250 (9.8) |

297 (11.7) |

200 (7.9) |

240 (9.4) |

51 (112) |

92 (209) |

||||

350 (14) |

92 (3.6) |

320 (12.6) |

297 (11.7) |

325 (12.8) |

290 (11.4) |

295 (11.6) |

65 (143) |

100 (220) |

||||

400 (16) |

102 (4.0) |

360 (14.2) |

327 (12.9) |

370 (14.6) |

290 (11.4) |

295 (11.6) |

86 (190) |

140 (309) |

||||

450 (18) |

114 (4.5) |

390 (15.4) |

355 (14.0) |

420 (16.5) |

335 (13.2) |

370 (14.6) |

110 (242) |

190 (419) |

||||

500 (20) |

127 (5.0) |

420 (16.5) |

385 (15.2) |

465 (18.3) |

335 (13.2) |

370 (14.6) |

140 (309) |

230 (507) |

||||

600 (24) |

154 (6.1) |

490 (19.3) |

475 (18.7) |

560 (22.0) |

445 (17.5) |

410 (16.1) |

220 (485) |

310 (683) |

||||

Materials |

|

Body / Insert |

CastironASTM- A126-Class B/EN 156fNo.EN-JL 1030 IDuctile Iron ASTM A536 Gr. 60-40-18/ EN 1563 NO.EN-JS 1024/ Carbon Steel ASTM A216 Gr. WCB |

Disc |

Ductile Iron ASTM A536 Gr. 60-40-18/ EN 1563 NO.EN-JS 1024/ Stainless Steel ASTM A217 CA 15/ ASTM A351 Gr. CF8/ CF8M, Even Rubber Lined. |

Seat |

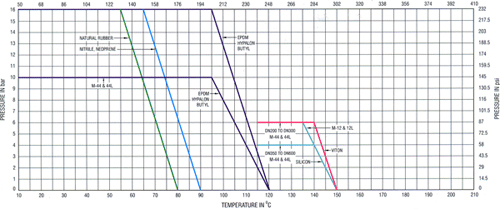

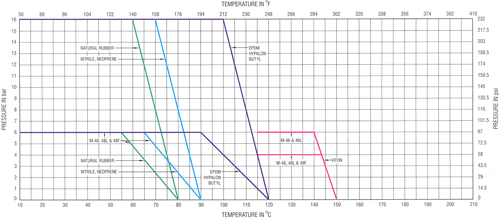

Nitrile 1 Neoprene 1 EPDM 1 Butyl 1 Viton 1 Silicon |

Stem |

Stainless Steel ASTM A276 Type 410/304/316 |

Stem Bearing |

Delrin |

Handle Unit |

Carbon Steel |

Gear Unit |

Housing in Cast Iron, Gear in S.G. Iron & Worm in EN8 |

Surface Protection for Ductile Iron |

Prime Coat: Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. |

| and Cast Carbon Steel Valves | Additional external coating: Black Stoving Enamel |

1) Nett in Kg. (Ibs) approx. (without obligation) * PN6 Pressure Rating for Valves with Silicon & Viton Seat & PN10 & PN6 Rating for Rubber Lined Disc for Model 12, 12L & 44, 44L respectively. * Concentric disc, Bi-directional, resilient seated, tight shut-off. * Worm Gear Actuators mandatory for Sizes 200mm (8") to 600mm (24"). * Valves can be supplied to suit ASME / BS / DIN Flanges. * Please Specify Working Pressure, Temperature & Service conditions. * Valves can be supplied with Locking, Extended Stem / Electrical I Pneumatic Actuators, and accessories like Limit Switch, Solenoid Valve, Air Filter Regulator, Positioner etc. .Other materials not mentioned above available on request.

FULLY COMPLIANT TO DESIGN STD : EN 593 & API 609 TESTING STD : EN 12266-1 & API 598

Test Pressure in bar (psi) |

||

Pressure rating |

PN16 |

PN6 |

Hyd. Shell |

24 (348) |

6 (131) |

| Seat | 17.6 (255) |

6.6 (96) |

| Air Seat | 6.9 (100) |

6.6 (96) |

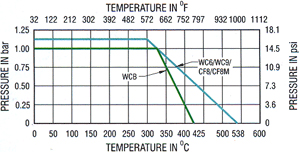

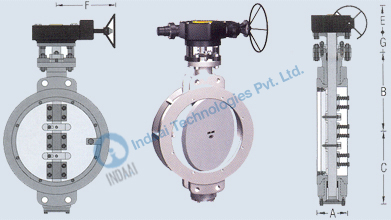

| Dimensions are in mm (inch) MODEL - 46 & 46L - PN16 RATING | |||||||||||

SIZE mm (Inch) |

A |

B |

C |

d |

E |

|

|||||

200 (8) |

60 (2.4) |

221 (8.7) |

175 (6.9) |

199 (7.8) |

170 (6,7) |

31. (68) |

46 (102) |

||||

250 (10) |

68 (2.7) |

250 (9.8) |

210 (8.3) |

247 (9.7) |

170 (6.7) |

40 (88) |

62 (137) |

||||

300 (12) |

78 (3.1) |

277 (10.9) |

250 (9.8) |

297 (11.7) |

200 (7.9) |

58 (128) |

102 (225) |

||||

350 (14) |

92 (3.6) |

320 (12.6) |

297 (11.7) |

325 (12.8) |

290 (11.4) |

76 (168) |

112 (247) |

||||

400 (16) |

102 (4.0) |

360 (14.2) |

327 (12.9) |

370 (14.6) |

290 (11.4) |

92 (203) |

146 (322) |

||||

450 (18) |

114 (4.5) |

390 (15.4) |

355 (14.0) |

420 (16.5) |

335 (13.2) |

120 (265) |

200 (441) |

||||

500 (20) |

127 (5.0) |

420 (16.5) |

385 (15.2) |

465 (18.3) |

335 (13.2) |

160 (353) |

240 (529) |

||||

600 (24) |

154 (6.1) |

490 (19.3) |

475 (18.7) |

560 (22.0) |

445 (17.5) |

245 (540) |

335 (738) |

||||

Dimensions are in mm (inch) MODEL - 46 & 46L - PN16 RATING |

|||||||||||

SIZE mm (Inch) |

A |

B |

C |

d |

E |

|

|||||

650 (26) |

165 (6.5) |

49'0(19:3) |

450 (17.7) |

616 (24.3) |

275 (10.8) |

175 (386) |

230 (507) |

||||

700 (28) |

165 (6.5) |

550 (21.7) |

500 (19.7) |

670 (26.4) |

352 (13.9) |

230 (507) |

365 (805) |

||||

750 (30) |

190 (7.5) |

610 (24.0) |

540 (21.3) |

715 (28.1) |

303 (1.1.9) |

275 (606) |

403 (889) |

||||

800 (32) |

190 (7.5) |

635 (25.0) |

560 (22.0) |

764 (30.1) |

303 (11.9) |

310 (683) |

490 (1080) |

||||

900 (36) |

203 (8.0) |

680 (26.8) |

640 (25.2) |

870 (34.3) |

318 (12.5) |

450 (992) |

700 (1543) |

||||

1000 (40) |

216 (8.5) |

740 (29.1) |

705 (27.8) |

970 (38.2) |

318 (12.5) |

570 (1257) |

840 (1852) |

||||

Materials |

|

Body / Insert |

Cast Iron ASTM A126 Class B / EN 1561 No.EN-Jr. 1030/ Ductile Iron ASTM A395 Gr. 60-40-18/ EN 1563 NO.EN-JS 1024/ Carbon Steel ASTM A216 Gr. WCB |

Disc |

Ductile Iron ASTM A395 Gr. 60-40-18/ EN 1563 NO.EN-JS 1024/ Stainless Steel ASTM A217 CA 15/ ASTM A351 Gr. CF8 / CF8M / Alluminium Bronze |

Seat 2) |

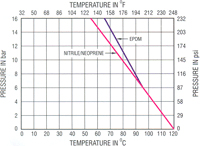

EPDM / Nitrile / Neoprene / Butyl |

Stem |

Stainless Steel ASTM A276 Type 410/ 304/316/ Monel |

Stem Bearing |

Poly Acetal (Delrin) |

Gear Unit |

Housing in Cast Iron, Gear in S.G. Iron & Worm in EN8 |

Surface Protection for Ductile Iron and Cast Carbon Steel Valves |

Prime Coat: Chlorine .free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional external Coating Black Stoving Enamel. |

1) Nett in Kg. (Ibs) approx. (Without obligation) 2) Bonded to body. * PN4 Pressure Rating for Rubber Lined Disc for Model 48, 48L & 48F. * Concentric disc, Bi-directional, resilient seated, tight shut-off. * Valves can be supplied to suit ASME / BS/ DIN Flanges. * Please Specify Working Pressure, Temperature & Service conditions. *Valves can be supplied with Locking, Extended Stem / Electrical / Pneumatic Actuators, and accessories like Limit Switch, Solenoid Valve, Air Filter Regulator, Positioner etc. * Other materials not mentioned above available on request.

Test Pressure in bar (psi) |

|||

| Pressure rating | PN16 |

PN10 |

PN6 |

| Hyd. Shell | 24 (348) |

15 (218) |

9 (131) |

| Seat | 17.6 (254) |

11 (160) |

6.6 (96) |

Air Seat |

6.9 (100) |

6.6 (96) |

|

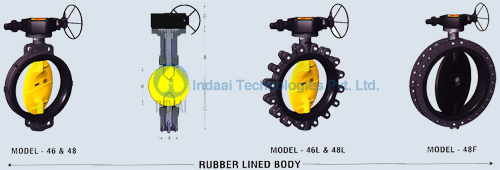

Dimensions are in mm (inch) |

||||||||||||||||||||||

Size mm (inch) |

|

B |

C |

d |

|

|

Wt 1) |

|||||||||||||||

80(3)

|

-

|

64(2.5)

|

135 (5.3)

|

95 (3.7)

|

48 (1.9)

|

30 (1.2)

|

-

|

300(11.8)

|

10 (22)

|

|||||||||||||

100(4) |

- |

64 (2.5) |

153 (6.0) |

105 (4.1) |

78 (3.1) |

30 (1.2) |

- |

300(11.8) |

- |

12(26) |

||||||||||||

125(5) |

70 (2.8) |

172 (6.8) |

125 (4.9) |

103(4.1) |

30 (1.2) |

30011.8) |

14(31) |

|||||||||||||||

150(6) |

- |

76 (3.0) |

185 (7.3) |

135 (5.3) |

128(5.0) |

30 (1.2) |

- |

300(11.8) |

- |

15(33) |

||||||||||||

200(8) |

- |

89 (3.5) |

221 (8.7) |

175 (6.9) |

160(6.3) |

74 (2.9) |

- |

450(17.7) |

- |

29(64) |

||||||||||||

250(10) |

- |

114(4.5) |

250 (9.8) |

210 (8.3) |

210(8.3) |

74 (2.9) |

- |

600(23.6) |

- |

36(79) |

||||||||||||

300(12) |

- |

114(4.5) |

277(10.9) |

240(9.4) |

260(10.2) |

74 (2.9) |

- |

600(23.6) |

52(115) |

|||||||||||||

350(14) |

78(3.1) |

127(5.0) |

320(12.6) |

315(12.4) |

- |

236 (9.3) |

236(9.3) |

240(9.4) |

138 (5.4) |

125(276) |

||||||||||||

400(16) |

102(4.0) |

140(5.5) |

360(14.2) |

350(13.8) |

270(10.6) |

270(10.6) |

320(12.6) |

170(6.7) |

155(342) |

|||||||||||||

450(18) |

114(4.5) |

152(6.0) |

390(15.4) |

385(15.2) |

- |

280(11.0) |

280(11.0) |

320(12.6) |

205(8.1) |

185(408) |

||||||||||||

500(20) |

127(5.0) |

152(6.0) |

420(16.5) |

420(16.5) |

360(14.2) |

360(14.2) |

365(14.4) |

275(10.8) |

250(551) |

|||||||||||||

600(24) |

154(6.1) |

178(7.0) |

500(19.7) |

508(20.0) |

403(15.9) |

403(15.9) |

385(15.2) |

365(14.4) |

350(772) |

|||||||||||||

700(28) |

165(6.5) |

229(9.0) |

565(22.2) |

540(21.3) |

- |

- |

615(24.2) |

650(25.6) |

620(24.4) |

550(1213) |

||||||||||||

800(32) |

190(7.5) |

241(9.5) |

630(24.8) |

650(25.6) |

- |

930(36.6) |

970(38.2) |

715(28.1) |

800(1764) |

|||||||||||||

900(36) |

203(8.0) |

241(9.5) |

695(27.4) |

735(28.9) |

- |

735(28.9) |

1270(48.4) |

930(36.6) |

950(2094) |

|||||||||||||

1000(40) |

216(8.5) |

300(11.8) |

745(29.3) |

765(30.1) |

- |

735(28.9) |

1350(53.1) |

1050(41.3) |

1100(2425) |

|||||||||||||

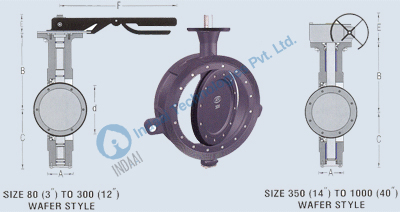

| Materials | |

Body |

Cast Iron ASTM A 126 Class B / EN 1561 NO.EN.JL 1040/ Ductile Iron ASTM A536 Gr. 60-40-18/ EN 1563 NO.EN-JS 1024 Carbon Steel ASTM A216 Gr. WCB / Stainless Steel ASTM A351 Gr. CF8/ CF8M / CN7M |

Disc |

Cast Iron ASTM A 126 Class B / EN 1561 NO.EN-JL 1040/ Ductile Iron ASTM A536 Gr. 60-40-18/ EN 1563 NO.EN-JS 1024 Carbon Steel ASTM A216 Gr. WCB / Stainless Steel ASTM A217 CA 15/ ASTM A351 Gr. CF8/ CF8M / CN7M |

Body Seat |

Stainless Steel ASTM A351 Gr. CF8 / CF8M / CN7M |

Disc Seal |

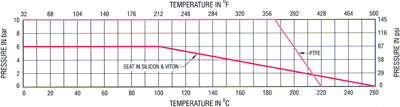

Nitrile / Neoprene / EPDM / Viton / Silicon / PTFE* |

Stem |

Stainless Steel ASTM A276 Type 410 / 304 / 316 / A-20 |

Stem Bearing |

Carbon Steel/Malleable Iron |

| Handle Unit | Housing in Cast Iron, Gear in S.G. Iron & Worm in EN8 |

Surface Protection for Valves |

Prime Coat: Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional external coating : Black Enamel |

1) Nett in Kg. (Ibs) approx. (without obligation) for Long series. *PN6 Rating for PTFE Seal. * Eccentric disc, Bi-directional, resilient seated, tight shut-off. * Body and Disc in Cast Iron! Ductile Iron available for Sizes 350mm (14") to 1000mm (40"). * Wonn Gear Actuators mandatory for Sizes 350mm (14") to 1000 (40"). * Valves can be supplied to suitASME! BS! DIN Flanges. * Please Specify Working Pressure, Temperature & Service conditions. * Valves can be supplied with Locking, Extended Stem! Electrical! Pneumatic Actuators, and accessories like Limit Switch, Solenoid Valve, Air Filter Regulator, Positioner etc. * Fabricated & cast construction with face to face dimensions of customers preference available on request. * Other materials not mentioned above available on request.

FULLY COMPLIANT TO DESIGN STD : EN 593 TESTING STD : EN 12266.1 & API59S

Test Pressure in bar (psi) |

|

| Pressure rating | PN6 |

| Hyd. Shell | 9 (131) |

| Seat | 1 (15) |

Air Seat |

1 (15) |

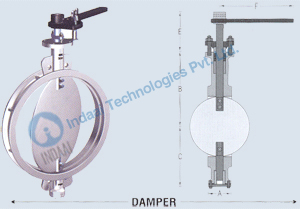

| Dimensions are in mm (inch) | |||||||

Size mm (inch) |

A |

B |

C |

E |

F |

G |

Wt 1) |

200 (8) |

60(2.5) |

221 (8.7) |

175 (6,9) |

155 (6.1) |

212 (8.3) |

90 (3.5) |

20 (44) |

250 (10) |

68 (2.7) |

250 (9.8) |

210 (8.3) |

155 (6.1) |

212 (8.3) |

90 (3.5) |

26 (57) |

300 (12) |

78 (3.1) |

277 (10.9) |

240 (9.4) |

185 (7.3) |

226 (8.9) |

90 (3.5) |

38 (84) |

350 (14) |

78 (3.1) |

320 (12.6) |

315 (12.4) |

236 (9.3) |

250 (9.8) |

90 (3.5) |

137 (302) |

400 (16) |

102 (4.0) |

360 (14.2) |

350 (13.8) |

270 (10.6) |

270 (10.6) |

120 (4.7) |

170 (375) |

450 (18) |

114 (4,5) |

390 (15.4) |

385 (15.2) |

280 (11.0) |

320 (12.6) |

120 (4.7) |

203 (448) |

500 (20) |

127 (5.0) |

420 (16,5) |

420 (16.5) |

360 (14,2) |

365 (14.4) |

120 (4.7) |

275 (606) |

600 (24) |

154 (6.1) |

500 (19.7) |

510 (20.1) |

403 (15.9) |

470 (18.5) |

120 (4.7) |

385 (849) |

700 (28) |

165 (6.5) |

565 (22.2) |

540 (21.3) |

445 (17.5) |

491 (19.3) |

150 (5,9) |

620 (1367) |

800 (32) |

190 (7.5) |

630 (24.8) |

650 (25.6) |

495 (19.5) |

491 (19.3) |

150 (5.9) |

820 (1808) |

900 (36) |

203 (8.0) |

695 (27.4) |

735 (28.9) |

495 (19.5) |

491 (19.3) |

150 (5.9) |

980 (2161) |

1000 (40) |

216 (8.5) |

745 (29.3) |

765 (30.1) |

520 (20.5) |

588 (23.1) |

150 (5.9) |

1140 (2513) |

1050 (42) |

216 (8.5) |

775 (30.5) |

800 (31.5) |

520 (20.5) |

588 (23.1) |

200 (7.9) |

1190 (2623) |

1200 (48) |

254 (10.0) |

840 (33.1) |

820 (32.3) |

520 (20.5) |

588 (23.1) |

200 (7.9) |

1310(2888) |

Materials |

|

Body |

CarbOii'Steel ASTM A21'6Gr:WCBn\STM A217 Gi:WC6i WC9 / Stainiess Steel AS-TM A351Gr. CF8 / CF8M |

Disc |

Carbon Steel ASTM A216 Gr. WCB / ASTM A217 Gr. WC6 / WC9 / Stainless Steel ASTM A351 Gr. CF8/ CF8M |

Disc Seal |

WCB+316/ WC6+316 / WC9+316 Edges for WCB /WC6 /WC9 disc only |

Body Seat |

Non Asbestos Graphite + Wire Reinforced |

Stem |

Stainless Steel ASTM A276 Type 410/304/316/ 17.4PH |

Spring |

SS316 |

| Gland Packing | Pre moulded Grafoil rings |

Stem Bearing |

ASTM A439 TYPE D2 NIRESIST |

Gear Unit |

Housing in Cast Iron, Gear in S.G. Iron & Worm in EN8/ EN19 |

Surface Protection for Ductile Iron and Cast Carbon Steel Valves |

Prime Coat: Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional external coating: Heat Resistant Silver Streak Aluminum Paint |

1) Nett in Kg. (Ibs) approx. (Without obligation) * Eccentric, spring assisted disc, Uni-directional, Leakage Rate Class V. * Valves can be supplied to suit ASME / BS / DIN Flanges. * Please Specify Working Pressure, Temperature & Service conditions. * Valves can be supplied with Locking, Extended Stem! Electrical! Pneumatic Actuators, and accessories like Limit Switch, Solenoid Valve, Air Filter Regulator, Positioner etc. * Fabricated with face to face dimensions of customers preference available on request.

DESIGN STD /I TESTING STD : MANUFACTURER'S STD.

Test Pressure in bar (psi) |

|

| Pressure rating | PN6 |

| Hyd. Shell | 9 (131) |

| Application : | |

Blast Furnace Gas |

Exhaust Gas |

Flue Gas |

Corex Gas |

Combustible Gases |

Hot Air |

Saturated steam |

Dimensions are in mm (inch) |

||||||

Size mm (inch) |

A |

B |

C |

E |

F |

Wt 1) |

80 (3) |

46 (1:8) |

135 (5.3) |

90 (3.5) |

100 (3.9) |

175 (6.9) |

12 (27) |

100 (4) |

52 (2.0) |

153 (6.0) |

118 (4.6) |

100 (3.9) |

200 (7.9) |

14 (31) |

150 (6) |

56 (2.2) |

185 (7.3) |

148 (5.8) |

100 (3.9) |

250 (9.8) |

17 (38) |

200 (8) |

60 (2.4) |

221 (8.7) |

185 (7.3) |

110 (4.3) |

250 (9.8) |

21 (46) |

250 (10) |

68 (2.7) |

250 (9.8) |

210 (8.3) |

120 (4.7) |

300 (11.8) |

25 (55) |

300 (12) |

78 (3.1) |

277 (10.9) |

250 (9.8) |

120 (4.7) |

300 (11.8) |

28 (62) |

350 (14) |

78 (3.1) |

320 (12.6) |

297 (11.7) |

130(5.1) |

350 (13.8) |

30 (66) |

400 (16) |

102 (4.0) |

360 (14.2) |

327 (12.9) |

130 (5.1) |

350 (13.8) |

34 (75) |

450 (18) |

114 (4.5) |

390 (15.4) |

355 (14.0) |

130 (5.1) |

350 (13.8) |

36 (79) |

500 (20) |

127 (5.0) |

420 (16.5) |

385 (15.1) |

130 (5.1) |

500 (19.7) |

48 (106) |

600 (24) |

154 (6.1) |

500 (19.7) |

475 (18.7) |

130 (5.1) |

500 (19.7) |

52 (115 |

700 (28) |

165 (6.5) |

565 (22.2) |

540 (21.3) |

* |

* |

90 (198) |

800 (32) |

190 (7.5) |

630 (24.8) |

650 (25.6) |

* |

* |

125 (276)J |

900 (36) |

203 (8.0) |

695 (27.4) |

735 (28.9) |

* |

* |

170 (375) |

1000 (40) |

216(8.5) |

745(29.3) |

765(30.1) |

* |

* |

210(463) |

Dimensions are in mm (inch) |

||||||

Size mm (inch) |

A |

B |

C |

E |

F |

Wt 1) |

80 (3) |

46 (1:8) |

135 (5.3) |

90 (3.5) |

100 (3.9) |

175 (6.9) |

12 (27) |

100 (4) |

52 (2.0) |

153 (6.0) |

118 (4.6) |

100 (3.9) |

200 (7.9) |

14 (31) |

150 (6) |

56 (2.2) |

185 (7.3) |

148 (5.8) |

100 (3.9) |

250 (9.8) |

17 (38) |

200 (8) |

60 (2.4) |

221 (8.7) |

185 (7.3) |

110 (4.3) |

250 (9.8) |

21 (46) |

250 (10) |

68 (2.7) |

250 (9.8) |

210 (8.3) |

120 (4.7) |

300 (11.8) |

25 (55) |

300 (12) |

78 (3.1) |

277 (10.9) |

250 (9.8) |

120 (4.7) |

300 (11.8) |

28 (62) |

350 (14) |

78 (3.1) |

320 (12.6) |

297 (11.7) |

130(5.1) |

350 (13.8) |

30 (66) |

400 (16) |

102 (4.0) |

360 (14.2) |

327 (12.9) |

130 (5.1) |

350 (13.8) |

34 (75) |

450 (18) |

114 (4.5) |

390 (15.4) |

355 (14.0) |

130 (5.1) |

350 (13.8) |

36 (79) |

500 (20) |

127 (5.0) |

420 (16.5) |

385 (15.1) |

130 (5.1) |

500 (19.7) |

48 (106) |

600 (24) |

154 (6.1) |

500 (19.7) |

475 (18.7) |

130 (5.1) |

500 (19.7) |

52 (115 |

700 (28) |

165 (6.5) |

565 (22.2) |

540 (21.3) |

* |

* |

90 (198) |

800 (32) |

190 (7.5) |

630 (24.8) |

650 (25.6) |

* |

* |

125 (276)J |

900 (36) |

203 (8.0) |

695 (27.4) |

735 (28.9) |

* |

* |

170 (375) |

1000 (40) |

216(8.5) |

745(29.3) |

765(30.1) |

* |

* |

210(463) |

| Materials | |

Body |

Carbon Steel ASTMA2'1'6Gr. WCB/ASTM A217 Gr. WC61 WC91 StainleSS Steel ASTM-A351 Gr. CF8/ CF8M |

Disc |

ASTM A515 Gr. 551 ASTM A240 TYPE 304/316 |

Stem |

Stainless Steel ASTM A276 Type 410 1 304/316/17 -4PH |

Gland Packing |

Pre moulded Grafoil rings |

Stem Bearing |

ASTM A439 TYPE D2 NIRESIST |

Handle Unit |

Carbon Steel 1 Malleable Iron |

| Surface Protection for | Prime Coat: Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional external coatining : Heat Resistant Silver Streak Aluminum Paint |

1) Nett in Kg. (Ibs) approx. (without obligation) * Worm Gear Actuators mandatory for Sizes 700mm (28") to 1000 (40"). * Concentric disc, Bi-directional, Low leakage Valves (2% ofCv) Valves can be supplied to suit ASMEI / BS / DIN Flanges. * Please Specify Working Pressure, Temperature & Service conditions. * Valves can be supplied with Locking, Extended Stem / Electrical / Pneumatic Actuators, and accessories like Limit Switch, Solenoid Valve, Air Filter Regulator, Positioner etc. * Fabricated & cast construction with face to face dimensions of customers preference available on request.

Size mm (inch) |

12,12L, 44, 44L, 46, 46L 48, 48L, 48F & 20 |

81 / 85F / 81 H |

85F (AWWA) |

32 (11/4) |

70 |

- |

- |

40 (11/2) |

96 |

- |

- |

50 (2) |

159 |

- |

- |

65 (21/2) |

266 |

- |

- |

80 (3) |

457 |

260 |

225 |

100 (4) |

860 |

475 |

400 |

125 (5) |

1320 |

770 |

- |

150 (6) |

2020 |

1125 |

1000 |

200 (8) |

3540 |

1500 |

1500 |

250 (10) |

5580 |

2400 |

2250 |

300 (12) |

8080 |

3450 |

3250 |

350 (14) |

8700 |

4700 |

4500 |

400 (16) |

12200 |

6600 |

6700 |

450 (18) |

15500 |

8400 |

8800 |

500 (20) |

18500 |

10400 |

10900 |

600 (24) |

22320 |

15000 |

15000 |

650 (26) |

26200 |

16740 |

- |

700 (28) |

30380 |

18000 |

- |

750 (30) |

34900 |

- |

22000 |

800 (32) |

39680 |

26000 |

- |

900 (36) |

50220 |

33700 |

33700 |

1000 (40) |

62000 |

41600 |

- |

1050 (42) |

68400 |

- |

47000 |

1200 (48) |

89300 |

60000 |

60000 |

1350 (54) |

- |

- |

74000 |

1400 (56) |

- |

82000 |

- |

1500 (60) |

- |

- |

95000 |

1600 (64) |

- |

106000 |

- |

1650 (66) |

- |

- |

135000 |

1800 (72) |

- |

- |

170000 |

Size mm (inch) |

81 HPN1 |

85F (AWWA) |

32 (11/4) |

- |

- |

40 (11/2) |

- |

- |

50 (2) |

- |

- |

65 (21/2) |

- |

- |

80 (3) |

- |

5 (3.7) |

100 (4) |

- |

10 (7.4) |

125 (5) |

- |

- |

150 (6) |

- |

15 (11.1) |

200 (8) |

30 (22.1) |

20 (14.8) |

250 (10) |

50 (36.9) |

35 (25.8) |

300 (12) |

92 (67.9) |

75 (55.4) |

350 (14) |

105 (77.5) |

95 (70.1) |

400 (16) |

160 (118.1) |

120 (88.6) |

450 (18) |

230 (169.7) |

180 (132.8) |

500 (20) |

325 (239.9) |

250 (184.5) |

600 (24) |

535 (394.8) |

440 (324.7) |

650 (26) |

- |

- |

700 (28) |

890 (656.8) |

768 (566.8) |

750 (30) |

- |

- |

800 (32) |

1450 (1070.1) |

1065 (786.0) |

900 (36) |

2068 (1526.2) |

1370 (1011.1) |

1000 (40) |

2930 (2162.3) |

1880 (1387.4) |

1050 (42) |

3220 (2376.4) |

- |

1200 (48) |

3585 (2645.7) |

- |

1350 (54) |

- |

- |

1400 (56) |

- |

- |

1500 (60) |

- |

- |

1600 (64) |

- |

- |

1650 (66) |

- |

- |

1800 (72) |

- |

- |

Model |

12,12L/46,46L PN16 |

44&44L PN10 |

48,48l&48F PN6 |

|

|

||||||||||||||||||||||

32 (11/4) |

7 (5.2) |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||||

40 (11/2) |

7 (5.2) |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||||

50 (2) |

9 (6.6) |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||||

65 (21/2) |

14 (10) |

- |

- |

9 (6.6) |

7 (5.2) |

5 (3.7) |

4 (3.0) |

- |

- |

||||||||||||||||||

80 (3) |

18 (13) |

- |

- |

13 (10) |

10 (7.4) |

8 |

6 (4.4) |

10 (7.4) |

- |

||||||||||||||||||

100 (4) |

35 (26) |

- |

- |

25 (19) |

18 (13) |

13 (9.6) |

10 (7.4) |

18 (13) |

- |

||||||||||||||||||

125 (5) |

55 (41) |

- |

- |

58 (43) |

35 (26) |

24 (18) |

19 (14) |

- |

- |

||||||||||||||||||

150 (6) |

75 (55) |

- |

- |

152 (112) |

52 (38) |

30 (22) |

24 (18) |

52 (38) |

- |

||||||||||||||||||

200 (8) |

140 (103) |

142 (105) |

- |

180 (133) |

110 (81) |

63 (47) |

37 (27) |

105 (78) |

- |

||||||||||||||||||

250 (10) |

205 (151) |

246 (182) |

- |

320 (236) |

195 (144) |

112 (83) |

65 (48) |

190 |

- |

||||||||||||||||||

300 (12) |

280 (207) |

352 (260) |

- |

495 (365) |

366 (270) |

178 (131) |

99 (73) |

313 (231) |

- |

||||||||||||||||||

350 (14) |

915 (675) |

420 (310) |

- |

685 (506) |

425 (314) |

273 (202) |

152 (112) |

490 (362) |

- |

||||||||||||||||||

400 (16) |

1342 (990) |

720 (531) |

- |

1035 (764) |

640 (472) |

405 (299) |

221 (163) |

735 (542) |

- |

||||||||||||||||||

450 (18) |

1880 (1387) |

1010 (745) |

- |

1460 (1077) |

915 (675) |

595 (439) |

308 (227) |

1050 (775) |

- |

||||||||||||||||||

500 (20) |

2664 (1966) |

1325 (978) |

- |

2085 (1539) |

1295 (956) |

842 (621) |

357 (263) |

1485 |

- |

||||||||||||||||||

600 (24) |

4337 (3201) |

2152 (1588) |

- |

3410 (2517) |

2135 (1576) |

1210 (893) |

489 (361) |

2860 (2111) |

- |

||||||||||||||||||

650 (26) |

- |

- |

1150 (849) |

4820 (3537) |

2830 (2089) |

1560 |

617 (455) |

- |

- |

||||||||||||||||||

700 (28) |

- |

- |

1535 (1133) |

5570 (4111) |

3563 (2630) |

1845 (1362) |

757 (559) |

- |

- |

||||||||||||||||||

750 (30) |

- |

- |

1855 (1369) |

- |

- |

- |

706 (521) |

5580 (4118) |

- |

||||||||||||||||||

800 (32) |

- |

- |

2130 (1572) |

9040 (6672) |

5800 (4280) |

2845 (2100) |

1390 (1026) |

- |

|||||||||||||||||||

900 (36) |

- |

- |

2740 (2022) |

14510 (10708) |

8270 (6103) |

4245 (3133) |

3140 (2317) |

9665 (7133) |

- |

||||||||||||||||||

1000 (40) |

- |

- |

3760 (2775) |

20450 (15092) |

11715 (8646) |

5695 (4203) |

3950 (2915) |

- |

- |

||||||||||||||||||

1050 (42) |

- |

- |

5190 (3830) |

- |

- |

14205 (10483) |

- |

||||||||||||||||||||

1200 (48) |

- |

- |

6280 (4635) |

- |

- |

10100 (7454) |

4860 (3587) |

8980 (6627)* |

4460 (3291) |

||||||||||||||||||

1350 (54) |

- |

- |

- |

- |

- |

12151 (8967)* |

6165 (4550) |

||||||||||||||||||||

1400 (56) |

- |

- |

- |

- |

- |

16635 (12277) |

8080 (5963) |

- |

- |

||||||||||||||||||

1500 (60) |

- |

- |

- |

- |

- |

- |

- |

16950 (12509)* |

9000 (6642) |

||||||||||||||||||

1600 (64) |

- |

- |

- |

- |

- |

27200 (20074) |

14000 (10332) |

- |

- |

||||||||||||||||||

1650 (66) |

- |

- |

- |

- |

- |

- |

- |

30594 (22578)* |

12045 (8889) |

||||||||||||||||||

1800 (72) |

- |

- |

- |

- |

- |

- |

- |

40810 (30118)* |

16020 (11823) |

||||||||||||||||||