Mobile No.

+91 97663 36366

Test Pressure in bar (psi) |

|||

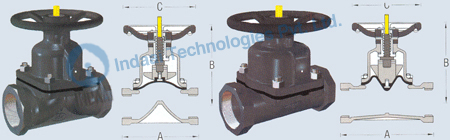

Series 's2k' |

Series 'G2k' |

||

Pressure rating 2) |

16 |

10 |

10 |

Hyd. Shell |

24 (348) |

15 (218) |

15.75 (218) |

Seat |

16 (232) |

10 (145) |

10 (145) |

Air Seat |

5 (73) |

5 (73) |

|

| Dimensions are in mm (inch) | |||||||||

| Size mm (inch) | A E, SWE, BWE CI Alloy | B | C | Wt 1) SE, SWE, BWE | A SCREWED Ends | B | C | Wt 1 | |

6(1/4) |

48 (1.9) | 108 (4.3) | 85 (3.3) | 70 (2.8) | 0.6 (1.3) | ||||

| 15 (1/2) | 64(2.5) | 108(4.3) | 85(3.3) | 70(2.8) | 0.9(2.0) | 64(2.5) | 90(3.5) | 70(2.8) | 0.9(2.0) |

| 20 (3/4) | 83 (3.3) | 117 (4.6) | 90 (3.5) | 70 (2.8) | 1.5 (3.3) | 83(3.3) | 90(3.5) | 70(2.8) | 1.8(4.0) |

| 25 (1) | 108 (4.3) | 127 (5.0) | 107 (4.2) | 100(3.9) | 2.1(4.6) | 108(4.3) | 112(4.4) | 100(3.9) | 3.0(6.6) |

| 32 (114) | 121 (4.7) | 146(5.7) | 115(4.5) | 100(3.9) | 3.5(7.7) | 121(4.7) | 112(4.4) | 100(3.9) | 3.2(7.0) |

| 40 (11/2) | 140 (5.5) | 159(6.3) | 146(5.7) | 140(5.5) | 4.9(10.8) | 140(5.5) | 112(4.4) | 100(3.9) | 3.5(7.7) |

| 50 (2) | 165 (6.5) | 190(7.5) | 156(6.1) | 140(5.5) | 6.4(14.1) | 165(6.5) | 146(5.7) | 140(5.5) | 6.5(14.3) |

| 65 (21/2) | 203 (8.0) | 216(8.5) | 173(6.8) | 180(7.1) | 9.6(21.2) | 203(8.0) | 177(7.0) | 180(7.1) | 10(22.0) |

| 80 (3) | 254(10.0) | 254(10.0) | 227(8.9) | 225(8.8) | 18(39.7) | 254(10.0) | 205(8.1) | 225(8.9) | 21(46.3) |

| 100 (4) | 305(12.0) | 255(10.0) | 225(8.9) | 26(57.3) | |||||

Materials |

|

Body /Bonnet/Compressor |

Cast Iron ASTM A126 Class B / EN-1561 NO.EN-JL1040 /SGlron EN-1563 No.EN-JS1024. |

Body Lining |

t Steel ASTM A743 Gr. CC50 / ASTM A216 Gr. WCB / Stainless Steel: ASTM A351 Gr. CF8/ CF8M / CN7M |

Diaphragm |

Natural/Butyl/Neoprene / EPDM / Nitrile / Hypalon / Viton / Silicon / PTFE etc. |

Stem |

Steel ASTM A276 TYPE 410 |

Bushing |

S Giron EN-1563 NO.EN-JS1050 |

Connecting studs / nuts |

Steel Gr. 4.6/4 |

| HandWheel | Cast Iron ASTM A 126 Class B / EN-1561 NO.EN-JL 1040 |

Surface Protection for Cast Iron and Cast Carbon Steel Valves |

Prime Coat: Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional external coating: Black Stoving Enamel |

1) Net in Kg. (Ibs) approx. (without obligation) 2) Pressure rating: Series 'S2K'for Sizes 6mm (1/4") to 50mm (2") -16 bar (232 psi), for Sizes 65mm (21/2") to 100mm (4") -10 bar (145 psi). * Face to Face Dimension (A) as per 'Weir BDK' Standard. * Standard Screwed ends to have BS : 21 (Parallel or Taper) or ASME B 1.20.1 (NPT) threads. Socket Weld ends as per ASME B 16.11 & Butt Weld ends as per ASME B 16.25 suitable for schedule 40/40S. * PleaseSpecify Working Pressure, Temperature & Service conditions. * Valves can be supplied with Pad -lock, Chainwheel, Travel Stop Arrangement, Extended type Stem, Electrical! Pneumatic Actuators & other accessories like Limit Switch,Solenoid Valve, Air Filtre Regulator, Positioner etc. * Other Materials not mentioned above available on request.

Test Pressure in bar (psi) |

|||

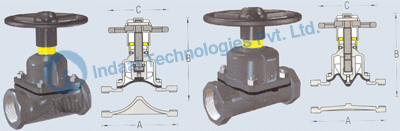

Series 's2k' |

Series 'G2k' |

||

Pressure rating 2) |

16 |

10 |

10 |

Hyd. Shell |

24 (348) |

15 (218) |

15.75 (218) |

Seat |

16 (232) |

10 (145) |

10 (145) |

Air Seat |

5 (73) |

5 (73) |

|

Dimensions are in mm (inch) |

||||||||||||||||

|

||||||||||||||||

Size mm (inch) |

|

B |

C |

Wt 1) SE, SWE, BWE |

A SCREWED Ends |

B |

C |

Wt 1) |

||||||||

15(1/2) |

64 (2.5) |

108 (4.3) |

105 (4.1) |

80 (3.1) |

0.9 (2.0) |

64 (2.5) |

105 (4.1) |

80 (3.1) |

0.9 (2.0) |

|||||||

20(3/4) |

83 (3.3) |

117 (4.6) |

115 (4.5) |

80 (3.1) |

1.5 (3.3) |

83 (3.3) |

115 (4.5) |

80 (3.1) |

1.8 (4.0) |

|||||||

25 (1) |

108 (4.3) |

127 (5.0) |

132 (5.2) |

120 (4.7) |

2.1 (4.6) |

108 (4.3) |

135 (5.3) |

120 (4.7) |

3.0 (6.6) |

|||||||

32 (11/4) |

121 (4.7) |

146 (5.7) |

140 (5.5) |

120 (4.7) |

3.5 (7.7) |

121 (4.7) |

135 (5.3) |

120 (4.7) |

3.2 (7.0) |

|||||||

40 (11/2) |

140 (5.5) |

159 (6.3) |

180 (7.1) |

120 (4.7) |

4.9 (10.8) |

140 (5.5) |

135 (5.3) |

120 (4.7) |

3.5 (7.7) |

|||||||

50 (2) |

165 (6.5) |

190 (7.5) |

210 (8.3) |

120 (4.7) |

6.4 (14.1) |

165 (6.5) |

175 (6.9) |

120 (4.7) |

6.5 (14.3) |

|||||||

65 (21/2) |

203 (8.0) |

216 (8.5) |

235 (9.3) |

180 (7.1) |

9.6 (21.2) |

203 (8.0) |

200 (7.9) |

250 (9.8) |

11 (24.3) |

|||||||

80 (3) |

254 (10.0) |

254 (10.0) |

305 (12.0) |

250 (9.8) |

18 (39.7) |

254 (10.0) |

250 (9.8) |

250 (9.8) |

22 (48.5) |

|||||||

100 (4) |

305 (12.0) |

340 (13.4) |

315 (12.4) |

27 (59.5) |

I |

- |

- |

|||||||||

Materials |

|

Body /Bonnet/Compressor |

Cast Iron ASTM A126 Class B / EN-1561 NO.EN-JL1040 / S Giron EN-1563 No.EN-JS1024. Cast Steel ASTM A743 Gr. CC50 / ASTM A216 Gr. WCB / Stainless Steel: ASTM A351 Gr. CF8/ CF8M / CN7M |

Diaphragm |

Natural/Butyl/Neoprene / EPDM / Nitrile / Hypalon / Viton / Silicon / PTFE etc. |

Stem |

Steel ASTM A276 TYPE 410 |

Bushing |

S Giron EN-1563 No.EN-JS1050 |

Connecting studs / nuts |

Steel Gr. 4.6/4 |

HandWheel |

Castlron ASTM A 126 Class B / EN-1561 NO.EN-JL 1040 |

| Surface Protection for Cast Iron and Cast Carbon Steel Valves | Prime Coat: Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional external coating: Black Stoving Enamel |

1) Netin Kg. (Ibs) approx. (without obligation) 2) Pressure rating: Series 'S2K'for Sizes 6mm (1/4")10 50mm (2") -16 bar (232 psi), for Sizes 65mm (21/2") to 100mm (4'') -10 bar (145 psi). * Face to Face Dimension (A) as per 'Weir BDK' Standard. * Standard Screwed ends to have BS : 21 (Parallel or Taper) or ASME B 1.20.1 (NPT) threads. Socket Weld ends as per ASME B16.11 & Butt Weld ends as per ASME B16.25 suitable for schedule 40/40S. * PleaseSpecify Working Pressure, Temperature & Service conditions. * Valves can be supplied with Pad -lock, Chainwheel, Travel Stop Arrangement, Extended type Stem, Electrical/ Pneumatic Actuators & other accessories like Limit Switch,Solenoid Valve, Air Filtre Regulator, Positioner etc. * Other Materials not mentioned above available on request.