Mobile No.

+91 97663 36366

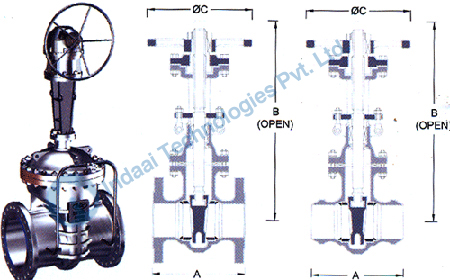

Features : Heavy duty as & Y type, bolted bonnet, rising stem, non rising hand wheel, renewable seatring for Carbon Steel Valves, integral for Stainless Steel Valves. Valves with most advanced design Features provide the ultimate in dependable, economic flow control.

Test Pressure in bar (psi) |

|||

Class |

150 |

300 |

600 |

Hyd. Shell |

30 (435) |

77 (1117) |

155 (2248) |

Seat |

22 (319) |

57 (827) |

113 (1639) |

Air Seat |

6.9 (100 |

||

Dimensions are in mm (inch) |

||||||||||||

Size |

Class -150 |

Class -300 |

Class - 600 |

|||||||||

|

mm (inch) |

A |

B |

C |

Wt 1) |

A |

B |

C |

Wt1) |

A |

B |

C |

Wt 1) |

15 |

108 |

210 |

100 |

4.0 |

140 |

210 |

100 |

4.6 |

||||

(1/2) |

(4.3) |

(8.3) |

(3.9) |

(9) |

(5.5) |

(8.3) |

(4.0) |

(10) |

||||

20 |

117 |

215 |

100 |

4.5 |

152 |

215 |

100 |

6 |

||||

(3/4) |

(4.6) |

(8.5) |

(3.9) |

(10) |

(6.0) |

(8.5) |

(4.0) |

(13) |

||||

25 |

127 |

250 |

150 |

6.2 |

165 |

250 |

150 |

7.5 |

||||

(1) |

(5.0) |

(9.8) |

(5.9) |

(14) |

(6.5) |

(9.8) |

(5.9) |

(17) |

||||

40 |

165 |

300 |

200 |

11.2 |

190 |

300 |

200 |

14.2 |

||||

(11/2) |

(6.5) |

(11.8) |

(7.9) |

(25) |

(7.5) |

(11.8) |

(7.9) |

(31) |

||||

50 |

178 |

345 |

200 |

16.5 |

216 |

345 |

200 |

19 |

292 |

405 |

250 |

30 |

(2) |

(7.0) |

(13.6) |

(7.9) |

(36) |

(8.5) |

(13.6) |

(7.9) |

(42) |

(11.5) |

(15.9) |

(9.8) |

(66) |

65 |

190 |

410 |

200 |

25 |

241 |

425 |

250 |

28 |

330 |

420 |

250 |

39 |

(21/2) |

(7.5) |

(16.1) |

(7.9) |

(55) |

(9.5) |

(16.7) |

(9.8) |

(62) |

(13.0) |

(16.5) |

(9.8) |

(86) |

80 |

203 |

435 |

250 |

27 |

282 |

460 |

250 |

43 |

356 |

460 |

300 |

51 |

(3) |

(8.0) |

(17.1) |

(9.8) |

(60) |

(11.1) |

(18.1) |

(9.8) |

(95) |

(14.0) |

(18.1) |

(11.8) |

(112) |

100 |

229 |

550 |

250 |

43 |

305 |

550 |

300 |

75 |

432 |

595 |

450 |

96 |

(4) |

(9.0) |

(21.7) |

(9.8) |

(95) |

(12.0) |

(21.7) |

(11.8) |

(165) |

(17.0) |

(23.4) |

(17.7) |

(212) |

125 |

254 |

650 |

300 |

55 |

381 |

685 |

450 |

98 |

508 |

690 |

450 |

135 |

(5) |

(10.0) |

(25.6) |

(11.8) |

(121) |

(15.0) |

(27.0) |

(17.7) |

(216) |

(20.0) |

(27.2) |

(17.7) |

(298) |

150 |

267 |

750 |

300 |

78 |

403 |

790 |

450 |

133 |

559 |

825 |

600 |

213 |

(6) |

(10.5) |

(29.5) |

(11.8) |

(172) |

(15.9) |

(31.1) |

(17.7) |

(293) |

(22.0) |

(32.5) |

(23.6) |

(470) |

200 |

292 |

960 |

450 |

125 |

419 |

990 |

450 |

215 |

660 |

1065 |

600 |

355 |

(8) |

(11.5) |

(37.8) |

(17.7) |

(276) |

(16.5) |

(39.0) |

(17.7) |

(474) |

(26.0) |

(41.9) |

(23.6) |

(783) |

250 |

330 |

1155 |

450 |

190 |

457 |

1230 |

600 |

368 |

787 |

1110 |

750 |

598 |

(10) |

(13.0) |

(45.5) |

(17.7) |

(419) |

(18.0) |

(48.4) |

(23.6) |

(811) |

(31.0) |

(43.7) |

(29.5) |

(1318) |

300 |

356 |

1390 |

600 |

288 |

502 |

1475 |

600 |

475 |

838 |

1770 |

* |

825 |

(12) |

(14.0) |

(54.7) |

(23.6) |

(635) |

(19.8) |

(58.1) |

(23.6) |

(1047) |

(33.0) |

(69.7) |

* |

(1819) |

350 |

381 |

1575 |

600 |

315 |

762 |

1310 |

750 |

580 |

||||

(14) |

(15.0) |

(62.0) |

(23.6) |

(695) |

(30.0) |

(51.6) |

(29.5) |

(1279) |

||||

400 |

406 |

1710 |

750 |

420 |

838 |

1870 |

* |

985 |

||||

(16) |

(16.0) |

(67.3) |

(29.5) |

(926) |

(33.0) |

(73.6) |

* |

(2172) |

||||

450 |

432 |

1950 |

750 |

650 |

914 |

2035 |

* |

1185 |

||||

(18) |

(17.0) |

(76.8) |

(29.5) |

(1433) |

(36.0) |

(80.1) |

* |

(2613) |

||||

500 |

457 |

2225 |

* |

725 |

991 |

2220 |

* |

1545 |

||||

(20) |

(18.0) |

(87.6) |

* |

(1598) |

(39.0) |

(87.4) |

* |

(3406) |

||||

600 |

508 |

2560 |

* |

1305 |

1143 |

2550 |

* |

1805 |

||||

(24) |

(20.0) |

(100.8) |

* |

(2877) |

(45.0) |

(100.4) |

* |

(3979) |

||||

650 |

559 |

2800 |

* |

1550 |

||||||||

(26) |

(22.0) |

(110.2) |

* |

(3417) |

||||||||

700 |

610 |

3050 |

* |

1880 |

||||||||

(28) |

(24.0) |

(120.1) |

* |

(4145) |

||||||||

750 |

610 |

3130 |

* |

2300 |

||||||||

(30) |

(24.0) |

(123.2) |

* |

(5071) |

||||||||

800 |

660 |

3280 |

* |

2550 |

||||||||

(32) |

(26.0) |

(129.1) |

* |

(5622) |

||||||||

900 |

711 |

3720 |

* |

3390 |

||||||||

(36) |

(28.0) |

(146.5) |

* |

(7474) |

||||||||

1) Nett in Kg. (Ibs) approx. (without obligation) for Flanged Ends. *Bevel Gear Actuators mandatory. * Butt Weld Ends to ASME B 16.25. * End to End dim. for Class 150 Butt Weld Ends as per manufacturer standard. * By-pass arrangement & Pressure Relief device available on request. * Please Specify Working pressure, Temperature & Service conditions. * Valves can be supplied with Electric or Gear Actuators. * Ring Joint, Large or Small Tongue & Groove Flanges are available on request.

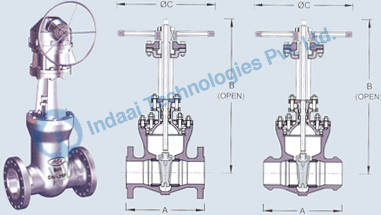

Features : Heavy duty OS & Y type, Pressure Seal Bonnet, rising stem, non rising handwheel, renewable seatring. wall thickness as per ASME B16.34, Valves with most advanced design Features provide the ultimate in dependable, economical flow control.

Test Pressure in bar (psi) |

|||

Class |

900 |

1500 |

2500 |

| Hyd. Shell | 230 (3335) |

384 (5568) |

647 (9282) |

Seat/Back Seat |

169(2451) |

282 (4089) |

474 (6873) |

Air Seat |

6.9 (100) |

||

| Dimensions are in mm (inch) | ||||||||||||||||||||||||||||||||

Size |

Class - 900 |

Class - 1500 |

Class - 2500 |

|||||||||||||||||||||||||||||

| mm (inch) |

|

B | C |

|

|

B | C |

|

A BWE |

B |

C |

Wt 1) |

||||||||||||||||||||

50 |

368 |

216 |

520 |

300 |

58 |

40 |

368 |

216 |

520 |

300 |

58 |

40 |

279 |

450 |

450 |

52 |

||||||||||||||||

(2) |

(14.5) |

(8.5) (20.5) |

(11.8) |

(128) |

(88) |

(14.5) |

(8.5) |

(20.5) |

(11.8) |

(128) |

(88) |

(11.0)(17.7)(17.7) |

(115) |

|||||||||||||||||||

65 |

419 |

254 |

595 |

450 |

86 |

55 |

419 |

254 |

595 |

450 |

86 |

55 |

330 |

520 |

600 |

79 |

||||||||||||||||

(21/2) |

(16.5) |

(10.0)(23.4) |

(17.7) |

(190) |

(121) |

(16.5) |

(10.0) |

(23.4) |

(17.7) |

(190) |

(121 ) |

(13.0)(20.5)(23.6) |

(174) |

|||||||||||||||||||

80 |

381 |

305 |

665 |

450 |

95 |

65 |

470 |

305 |

650 |

600 |

115 |

76 |

368 |

575 |

* |

105 |

||||||||||||||||

(3) |

(15.0) (12.0) |

(26.2) |

(17.7) |

(209) |

(143) |

(18.5) (12.0)(25.6) |

(23.6) |

(254) |

(168) |

(14.5) (22.6) |

* |

(232) |

||||||||||||||||||||

100 |

457 |

356 |

760 |

600 |

130 |

87 |

546 |

406 |

760 |

* |

171 |

106 |

457 |

685 |

* |

148 |

||||||||||||||||

(4) |

(18.0) (14.0) |

(29.9) |

(23.6) |

(287) |

(192) |

(21.5) (16.0) 29.9) |

* |

(377) |

(234) |

(18.0) (27.0) |

* |

(326) |

||||||||||||||||||||

125 |

559 |

432 |

885 |

600 |

200 |

140 |

673 |

483 |

910 |

* |

285 |

190 |

533 |

820 |

* |

450 |

||||||||||||||||

(5) |

(22.0) (17.0) (34.8) (23.6) |

(441) |

(309) |

(26.5) (19.0) 35.8) |

* |

(628) |

(419) |

(21.0) (32.3) |

* |

(992) |

||||||||||||||||||||||

150 |

610 |

508 |

1070 |

* |

330 |

250 |

705 |

559 |

1070 |

* |

440 |

262 |

610 |

990 |

* |

510 |

||||||||||||||||

(6) |

(24.0) |

(20.0)(42.1) |

* |

(728) |

(551) |

(27.8) (22.0)(42.1) |

* |

(970) |

(578) |

(24.0) (39.0) |

* |

(1124) |

||||||||||||||||||||

200 |

737 |

660 |

1415 |

* |

595 |

415 |

832 |

711 |

1475 |

* |

875 |

558 |

762 |

1350 |

* |

1050 |

||||||||||||||||

(8) |

(29.0) |

(26.0) |

(55.7) |

* |

(1312) |

(915) |

(32.8) |

(28.0) |

(58.1) |

* |

(1929)(1230) |

(30.0) (53.1) |

* |

(2315) |

||||||||||||||||||

250 |

838 |

787 |

1525 |

* |

795 |

610 |

991 |

863 |

1525 |

* |

1325 |

889 |

914 |

1706 |

* |

1265 |

||||||||||||||||

(10) |

(33.0) |

(31.0) |

(60.0) |

* |

(1753) |

(1345) |

(39.0) |

(34.0) |

(60.0) |

* |

(2921) |

(1960) |

(36.0) |

(67.2) |

* |

(2789) |

||||||||||||||||

300 |

965 |

914 |

1610 |

* |

1110 |

860 |

1130 |

990 |

1610 |

* |

2525 |

1580 |

991 |

2145 |

* |

1505 |

||||||||||||||||

(12) |

(38.0) |

(36.0) |

(63.4) |

* |

(2447) |

(1896) |

(44.5) |

(39.0) |

(63.4) |

* |

(5567) |

(3483) |

(39.0) |

(84.4) |

* |

(3318) |

||||||||||||||||

Materials |

|

Body & Bonnet |

ASTM A216 Gr. WCB, A217 Gr. WC6/ WC9 / C5 / C12, A351 Gr. CF8 / CF8M / CF3 / CF3M |

Wedge & Seat Ring |

ASTM A216 Gr. WCB, A217 Gr. WC6, A351 Gr. CF8 / CF8M / CF3 / CF3M, Seat faces are stellited |

Stem & Gland |

ASTM A276 TYPE 410/304/316 |

Yoke Sleeve |

Ni-Resist ASTM A439 Gr. D2 |

Gland Packing |

Pre moulded Grafoil rings / Braided + Moulded Grafoil rings. |

Pressure Seal Ring |

Expanded Graphite |

Stud / Nut |

ASTM A 193 Gr. B7/ B16 / B8 / B8M / A 194 Gr. 2H / 7 / 8 / 8M |

Yoke & Hand Wheel |

Carbon Steel, Alloy Steel |

Surface Protection for Carbon Steel Valves |

Prime Coat: Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional extemal coating: Silver Streak aluminium paint |

1) Nett in Kg. (Ibs) approx. (without obligation) *Bevel Gear Actuators mandatory. * For Class 2500. * Butt Weld Ends to ASME B16.25. * Class 2500 Valves are with Butt Weld Ends (Short pattern), Flanged Ends available on request. * By-pass arrangement & Pressure Relief device available on request. * Please Specify Working pressure, Temperature & Service conditions. * Valves can be supplied with Electric or Gear Actuators.* Ring Joint, Large or Small Tongue & Groove Flanges are available on request. * Other Materials not mentioned above available on request.

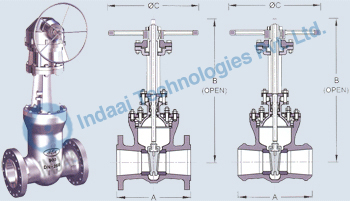

Features : Heavy duty OS & Ytype, Pressure Seal Bonnet, rising stem, non rising handwheel, renewable seatring. wall thickness as per ASME B16.34, Valves with most advanced design Features provide the ultimate in dependable, economical flow control.

Test Pressure in bar (psi) |

||

Class |

900 |

1500 |

Hyd. Shell |

230 (3335) |

384 (5568) |

Seat/Back Seat |

169(2451) |

282 (4089) |

Air Seat |

6.9 (100) |

|

| Dimensions are in mm (inch) | ||||||||||||||||||||||||||||

| Size | Class - 900 |

Class - 1500 |

||||||||||||||||||||||||||

| mm (inch) |

|

B |

C |

|

|

B |

C |

|

||||||||||||||||||||

50 x 32 |

368 |

216 |

450 |

250 |

47 |

34 |

368 |

216 |

450 |

250 |

47 |

34 |

||||||||||||||||

(2 x 11/4) |

(14.5) |

(8.5) |

(17.7) |

(9.8) |

(104) |

(75) |

(14.5) |

(8.5) |

(17.7) |

(9.8) |

(104) |

(75) |

||||||||||||||||

65 x 40 |

419 |

254 |

480 |

250 |

59 |

39 |

419 |

254 |

480 |

250 |

59 |

39 |

||||||||||||||||

(21/2x11/2) |

(16.5) |

(10.0) |

(18.9) |

(9.8) |

(130) |

(86) |

(16.5) |

(10.0) |

(18.9) |

(9.8) |

(130) |

(86) |

||||||||||||||||

80 x 50 |

381 |

305 |

510 |

300 |

65 |

43 |

470 |

305 |

510 |

300 |

84 |

48 |

||||||||||||||||

(3 x 2) |

(15.0) |

(12.0) |

(20.1) |

(11.8) |

(143) |

(95) |

(18.5) |

(12.0) |

(20.1) |

(11.8) |

(185) |

(106) |

||||||||||||||||

100 x 80 |

457 |

356 |

675 |

450 |

101 |

65 |

546 |

406 |

675 |

600 |

123 |

71 |

||||||||||||||||

(4 x 3) |

(18.0) |

(14.0) |

(26.6) |

(17.7) |

(223) |

(143) |

(21.5) |

(16.0) |

(26.6) |

(23.6) |

(271) |

(157) |

||||||||||||||||

125 x 80 |

559 |

432 |

675 |

450 |

154 |

95 |

673 |

483 |

675 |

600 |

205 |

105 |

||||||||||||||||

(5 x 3) |

(22.0) |

(17.0) |

(26.6) |

(17.7) |

(340) |

(209) |

(26.5) |

(19.0) |

(26.6) |

(23.6) |

(452) |

(232) |

||||||||||||||||

150 x 100 |

610 |

508 |

725 |

600 |

192 |

119 |

705 |

559 |

725 |

750 |

257 |

137 |

||||||||||||||||

(6 x 4) |

(24.0) |

(20.0) |

(28.5) |

(23.6) |

(423) |

(262) |

(27.8) |

(22.0) |

(28.5) |

(29.5) |

(567) |

(302) |

||||||||||||||||

200 x 150 |

737 |

660 |

1065 |

* |

380 |

222 |

832 |

711 |

1085 |

* |

515 |

322 |

||||||||||||||||

(8 x 6) |

(29.0) |

(26.0) |

(41.9) |

* |

(838) |

(489) |

(32.8) |

(28.0) |

(42.7) |

* |

(1135) |

(710) |

||||||||||||||||

250 x 200 |

838 |

787 |

1306 |

* |

518 |

355 |

991 |

863 |

1495 |

* |

806 |

494 |

||||||||||||||||

(10 x 8) |

(33.0) |

(31.0) |

(51.4) |

* |

(1142) |

(783) |

(39.0) |

(34.0) |

(58.9) |

* |

(1777) |

(1089) |

||||||||||||||||

300 x 250 |

965 |

914 |

1420 |

* |

925 |

710 |

1130 |

990 |

1595 |

* |

1375 |

910 |

||||||||||||||||

(12 x 10) |

(38.0) |

(36.0) |

(55.9) |

* |

(2039) |

(1565) |

(44.5) |

(39.0) |

(62.8) |

* |

(3031) |

(2006) |

||||||||||||||||

Materials |

|

Body & Bonnet |

ASTM A216 Gr. WCB, A217 Gr. WC6 / WC9 / C5 / C12, A351 Gr. CF8/ CF8M / CF3 / CF3M |

Wedge & Seat Ring |

ASTM A216 Gr. WCB, A217 Gr. WC6, A351 Gr. CF8 / CF8M / CF3 / CF3M, Seal faces are stellited |

Stem & Gland |

ASTM A276 TYPE 410/304/316 |

Yoke Sleeve |

Ni-Resist ASTM A439 Gr. D2 |

Gland Packing |

Pre moulded Grafoil rings / Braided Grafoil rings. |

Pressure Seal Ring |

Expanded Graphite |

Stud / Nut |

ASTM A 193 Gr. B7 / B 16 / B8 / B8M / A 194 Gr. 2H / 7 / 8 / 8M |

Yoke & Hand Wheel |

Carbon Steel, Alloy Steel |

Surface Protection for Carbon Steel Valves |

Prime Coat : Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional external coating: Silver Streak aluminium paint |

1) Nett in Kg. (Ibs) approx. (without obligation) * Bevel Gear Actuators mandatory. . Butt Weld Ends to ASME B16.25. * By-pass arrangement & Pressure Relief device available on request. * Please Specify Working pressure, Temperature & Service conditions. * Valves can be supplied with Electric or Gear Actuators. * Ring Joint, Large or Small Tongue & Groove Flanges are available on request. *Other Materials not mentioned above available on request.

| Torque values in Nm (Ft. lbs.) 100% P | |||||||||

Size |

GATE, CLASS |

VENTURI GATE, CLASS |

|||||||

mm (inch) |

150 |

300 |

600 |

900 |

1500 |

2500 |

900 |

1500 |

|

15 |

2 |

5 |

|||||||

20 |

3 |

6 |

|||||||

25 |

4 |

10 |

|||||||

40 |

7 |

17 |

|||||||

50 |

8 |

20 |

23 |

54 |

90 |

116 |

25 |

30 |

|

65 |

9 |

22 |

33 |

77 |

128 |

145 |

32 |

38 |

|

80 |

13 |

35 |

48 |

116 |

188 |

192 |

45 |

76 |

|

100 |

20 |

60 |

73 |

169 |

269 |

309 |

100 |

162 |

|

125 |

28 |

92 |

95 |

287 |

449 |

568 |

128 |

203 |

|

150 |

40 |

104 |

219 |

427 |

671 |

843 |

153 |

242 |

|

200 |

41 |

115 |

337 |

825 |

1299 |

2020 |

397 |

617 |

|

250 |

66 |

186 |

586 |

1034 |

1728 |

2285 |

766 |

1192 |

|

300 |

92 |

349 |

915 |

1598 |

3091 |

6219 |

999 |

1786 |

|

350 |

130 |

452 |

|||||||

400 |

171 |

672 |

|||||||

450 |

239 |

800 |

|||||||

500 |

315 |

1151 |

|||||||

600 |

512 |

1822 |

|||||||

650 |

645 |

2005 |

|||||||

700 |

820 |

2465 |

|||||||

750 |

935 |

3370 |

|||||||

800 |

1150 |

4080 |

|||||||

900 |

1365 |

4729 |

|||||||